jaw crusher kinematics simulation and analysis

Jaw crusher kinematics simulation and analysis

Jaw crusher kinematics simulation and analysis crusher 97 Page Figure 2 double cavity jaw crusher drive and restraint 232 impose constraints and drive the simulation model Before the establishment of a good geometry, motion analysis and calculation, use the movement of eachJaw crusher kinematics simulation and analysis International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 23209364, ISSN (Print): 23209356 Volume 3 Issue 3 ǁ March 2015 ǁ PP9599 Jaw crusher kinematics simulation and analysis Xiaodong Guo, Tao Yang, Caixia Lv, Longmei Dong School of Mechanical (PDF) Jaw crusher kinematics simulation and analysis May 06, 2015 Jaw crusher kinematics simulation and analysis 1 International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 23209364, ISSN (Print): 23209356 Volume 3 Issue 3 ǁ March 2015 ǁ PP9599 95 Page Jaw crusher kinematics simulation and analysis Xiaodong Guo, Tao Yang, Caixia Lv, Longmei Dong School of Mechanical Jaw crusher kinematics simulation and analysis

Jaw Crusher Kinematics Simulation and Analysis

Jaw crusher kinematics simulation and analysis Free download as PDF File (pdf), Text File (txt) or read online for free Jaw crusher is a kind of the relatively new compound pendulum jaw crusher, it has two crushing chamber and has an inverted crank rocker mechanism The design is mainly to meet the following requirements: 1, crusher capacity 3050t / h 2, the maximum grain size of the In this paper, outmoving jaw crusher machine is regarded as the research object and we established the simulation model of virtual prototype based on Nastran Through the simulation analysis of the movement process, trajectories of moving jaw side plate and a movable jaw toggle plate and related parameters were obtained and compared and verify the simulation model and theory modelResearch on the Kinematics Simulation of OutMoving Jaw crusher is 3:1 to 5:1 This paper focuses on review of a work done by researchers in the field of kinematic and dynamic analysis of jaw crusher attachments Kinematic and dynamic analysis is very useful to understand and improve the quality of jaw crushers Keywords–Jaw crusher, Kinematic analysis, Dynamic analysis I IntroductionStudy of Kinematic and Dynamic Analysis of Jaw Crusher A

Study of Kinematic and Dynamic Analysis of Jaw Crusher A

crusher is 3:1 to 5:1 This paper focuses on review of a work done by researchers in the field of kinematic and dynamic analysis of jaw crusher attachments Kinematic and dynamic analysis is very useful to understand and improve the quality of jaw crushers Keywords–Jaw crusher, Kinematic analysis, Dynamic analysis I IntroductionDownload Citation Modeling simulation and kinematic analysis based on Pro/Engineer for jaw crusher mechanism Pro/Engineer is a parametric featurebased design of Modeling simulation and kinematic analysis based on Pro In this paper, outmoving jaw crusher machine is regarded as the research object and we established the simulation model of virtual prototype based on Nastran Through the simulation analysis of the movement process, trajectories of moving jaw side plate and a movable jaw toggle plate and related parameters were obtained and compared and verify the simulation model and theory modelResearch on the Kinematics Simulation of OutMoving Jaw

jaw crusher virtual prototype simulation parameters

Jaw crusher kinematics simulation and analysis 1 International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 23209364, ISSN (Print): 23209356 Volume 3 Issue 3 ǁ March 2015 ǁ PP9599 95 Page Jaw crusher kinematics simulation and analysis Xiaodong Guo, Tao Yang, Caixia Lv, Longmei Dong Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi , (2015),"Analysis of the singleJournal of Engineering, Design and TechnologyThis paper provides the background of swing jaw plate of jaw crusher Kinematics to carried out further research work in fature Page 16391641 [9] Yuming Guan, Zhitao Zhang, Qianwei Zhang, (2011) IEEE, “Modeling Simulation and Kinematic Analysis Base On Pro/Engineer For Jaw Crusher Mechanism” Hebei University Of Technology Hebut Tianjin (PDF) A Review on Study of Jaw Plates of Jaw Crusher

Jaw Crusher Simulation Crusher Mills, Cone Crusher, Jaw

The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws cone crusher simulation 01:15: Cone Crusher,Cone Crusher,Crusher jaw crusher computation pdf • "PointLoadDeformation Relationships and Design of Jaw Crusher Plates," (with G R discrete event system simulation 5e PPT Powerpoint Jaw crusher kinmatic scheme Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Jaw crusher kinmatic scheme, quarry, aggregate, and different kinds of mineralsJaw crusher kinmatic schemeCrusher Contact India; Crusher Jaw Plate In India; rock crusher for gold separation; Jaw CrusherUsed Crusher Equipment Plant Prices; cans crushing product line; duoling stone horizontal shaft impact crusher; quartz crusher manufacturers zambia; 250 400 mobile jaw crusher plant sale; Cone Crusher Best Way Grinding; Gold Mining Equipment Tracksjaw crusher and analysis

parameters of jaw crusher

Jan 25, 2021 Jaw Crusher Kinematics Simulation And Analysis the tooth plate And the formula for calculating dualchamber jaw crusher main parameters, the single, the main performance parameters of dualchamber jaw crusher is relatively certain that the dualchamber jaw crusher machine performance, is a farreaching development a new type of potential 22 Jaw crusher kinematics simulation and analysis jaw crusher Design study of the current status of the development of the jaw crusher and the future trend of development and the design parameters of the detailed calculations And the most important is the use of ADAMS software crusher kinematics simulation and analysisJaw Crusher Current cbcaraudioplJaw crusher kinematics simulation and analysis crusher 97 Page Figure 2 double cavity jaw crusher drive and restraint 232 impose constraints and drive the simulation model Before the establishment of a good geometry, motion analysis and calculation, use the movement of eachJaw crusher kinematics simulation and analysis

(PDF) Jaw crusher kinematics simulation and analysis

Jaw crusher kinematics simulation and analysis International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 23209364, ISSN (Print): 23209356 Volume 3 Issue 3 ǁ March 2015 ǁ PP9599 Jaw crusher kinematics simulation and analysis Xiaodong Guo, Tao Yang, Caixia Lv, Longmei Dong School of Mechanical May 06, 2015 Jaw crusher kinematics simulation and analysis 1 International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 23209364, ISSN (Print): 23209356 Volume 3 Issue 3 ǁ March 2015 ǁ PP9599 95 Page Jaw crusher kinematics simulation and analysis Xiaodong Guo, Tao Yang, Caixia Lv, Longmei Dong School of Mechanical Jaw crusher kinematics simulation and analysisDownload Citation Modeling simulation and kinematic analysis based on Pro/Engineer for jaw crusher mechanism Pro/Engineer is a parametric featurebased design of Modeling simulation and kinematic analysis based on Pro

Research on the Kinematics Simulation of OutMoving Jaw

In this paper, outmoving jaw crusher machine is regarded as the research object and we established the simulation model of virtual prototype based on Nastran Through the simulation analysis of the movement process, trajectories of moving jaw side plate and a movable jaw toggle plate and related parameters were obtained and compared and verify the simulation model and theory modelcrusher is 3:1 to 5:1 This paper focuses on review of a work done by researchers in the field of kinematic and dynamic analysis of jaw crusher attachments Kinematic and dynamic analysis is very useful to understand and improve the quality of jaw crushers Keywords–Jaw crusher, Kinematic analysis, Dynamic analysis I IntroductionStudy of Kinematic and Dynamic Analysis of Jaw Crusher A Analysis of the single toggle jaw crusher kinematics Purpose – This paper aims to obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher Design/methodology/approach – The swing jaw drive mechanism of a single toggle jaw crusher is modelled as a planar crank and rocker Analysis of the single toggle jaw crusher kinematics

(PDF) Analysis of the Single Toggle Jaw Crusher Kinematics

jaw crusher, it is important to understand the kinematics of the swing jaw This paper sets out to obtain a complete kinematical description of the single toggle jaw crusher, from first principlesPro/Engineer is a parametric featurebased design of 3D software, with parametric modeling functions To reduce the development cycle and improve the design quality of jaw crusher, this paper takes full advantage of the Function module of the Pro/Engineer platform to make model simulation and dynamic analysis on the actual jaw crusher mechanism, and provided the updated path for the design and Modeling simulation and kinematic analysis based on Pro Jul 25, 2019 Crushing is a common step in mineral processing and an optimized design and crusher operation is key to maximizing productivity This video shows the analysiEDEM Simulation and Analysis of Jaw Crusher Process YouTube

Journal of Engineering, Design and Technology

Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi , (2015),"Analysis of the singleMay 05, 2015 May 05, 2015 – This paper aims to obtain equations that can be used to describe the motion of any given point in the swing jaw of a single toggle jaw crusher , – The swing jaw drive mechanism of a single toggle jaw crusher is modelled as a planar crank and rocker mechanism with the swing jaw as the coupler link Starting with the vector loop closure equation for the mechanism, Analysis of the single toggle jaw crusher kinematics Abstract Taking the working device of PE1500 × 1800compound pendulum jaw crusher as the research object, 3D model of working devices of four different cavity shape compound pendulum jaw crushers is carried out by using SolidWorks, and then the kinematic simulation software ADAMS is imported to carry out the kinematic simulation, and the horizontal and vertical displacement change curves of Simulation Analysis of Cavity Shape of Compound Pendulum

Jaw Crusher Simulation Crusher Mills, Cone Crusher, Jaw

The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws cone crusher simulation 01:15: Cone Crusher,Cone Crusher,Crusher jaw crusher computation pdf • "PointLoadDeformation Relationships and Design of Jaw Crusher Plates," (with G R discrete event system simulation 5e PPT Powerpoint

- crushing and mining equipment manufacturers in australia

- limit of a aggregate impact value test is 383

- micro powder talc powder air jet mill

- professional rock crusher manufacturer

- stone vertical roller mill

- rolling mills grinding

- ore crusher ore mining

- the quartz mobile crushing plant price for supplier is disunt

- stone crusher untuk jenis sendary crusher,stone crusher usa

- working and use jaw crusher

- cement plant cement plant

- Used Grinding Technology

- barite beneficiation process turkey

- iron ore ball crushing machine process flow chart

- stone crushers generator

- cde wash plant for sale australia

- Advantage and disadvantages of vibratory and rotary screen in

- Stone Crushing Machine Ireland

- granite aggregate supplier crusher Machine For Sale

- alluvial gold spiral chute

- stone crushing equip

- least st of stone crusher plant in indian feb

- Quarry Research Report Malaysia

- crushing and screening plants sales jobs in south india

- ntinuous vacuum belt filter press for mines

- magnetic base for surface grinder

- iron ore crusher mining crushing process image

- silica and sand mining

- china reasonable and popular ceramic ball mill price

- slag quarry equipment price in tanzania

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

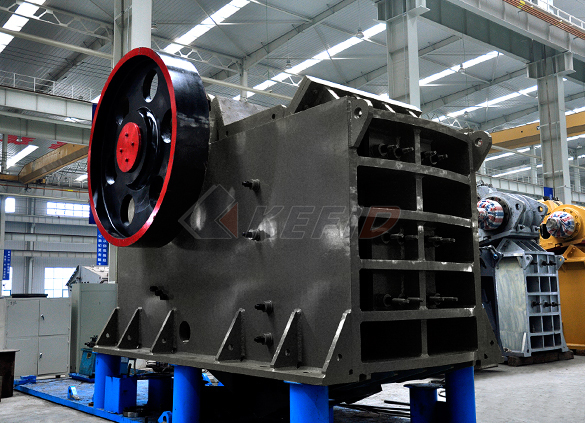

C6X series jaw crusher

JC series jaw crusher

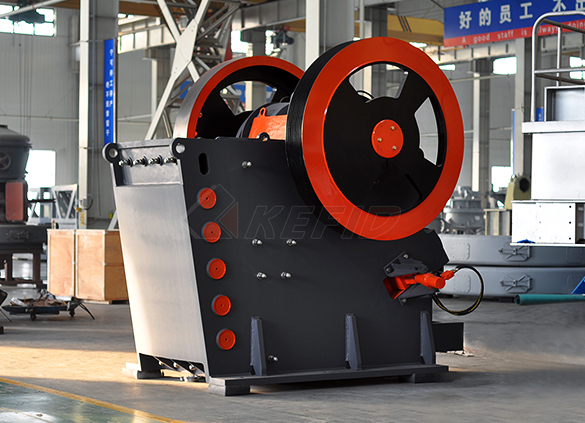

Jaw crusher

HJ series jaw crusher

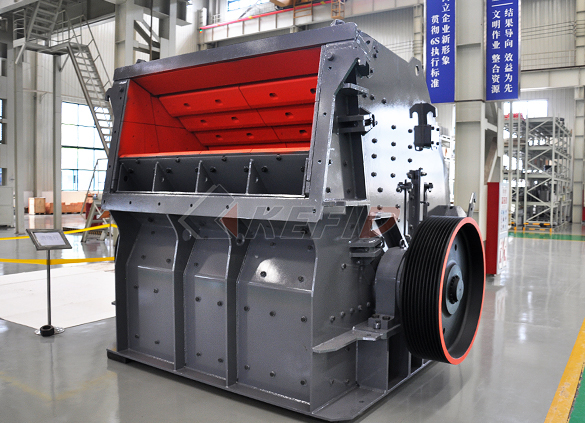

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

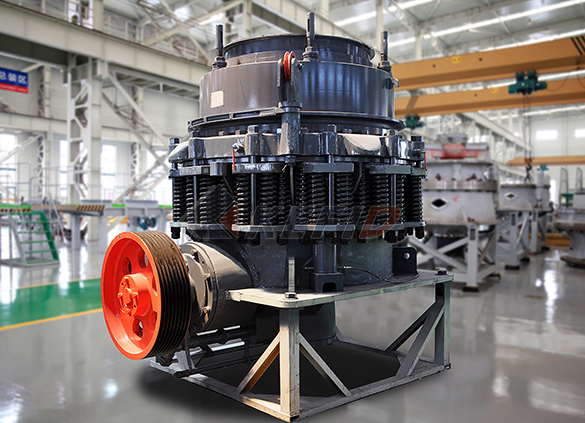

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

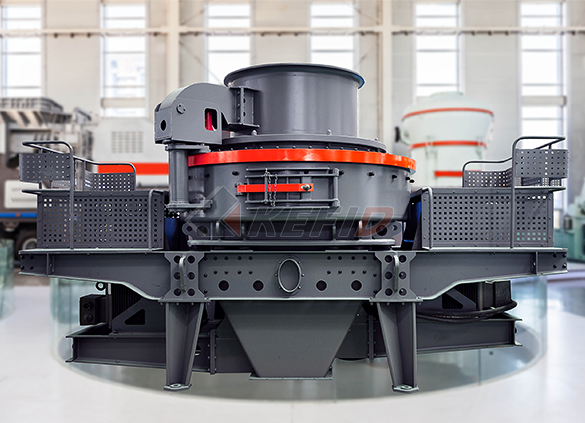

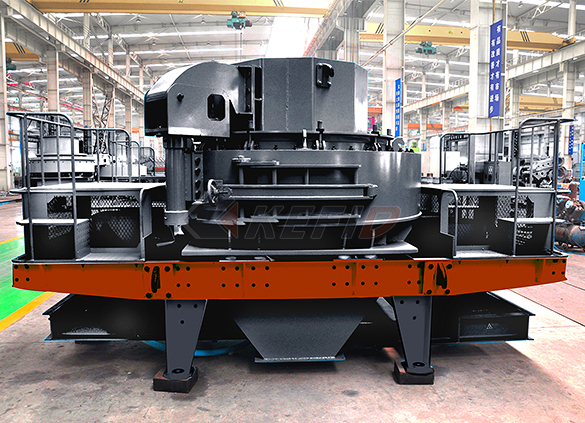

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

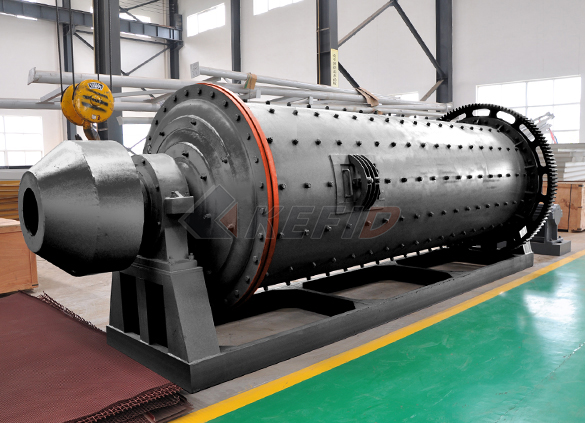

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

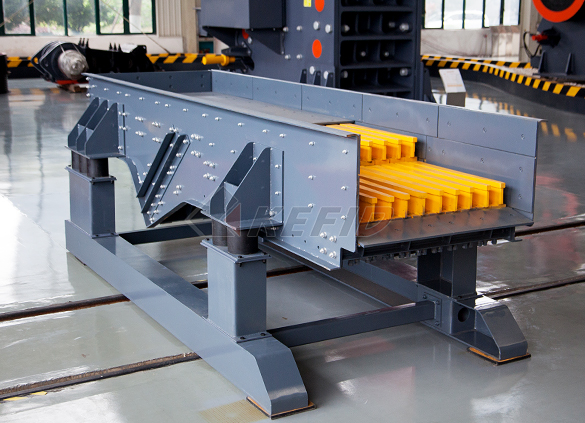

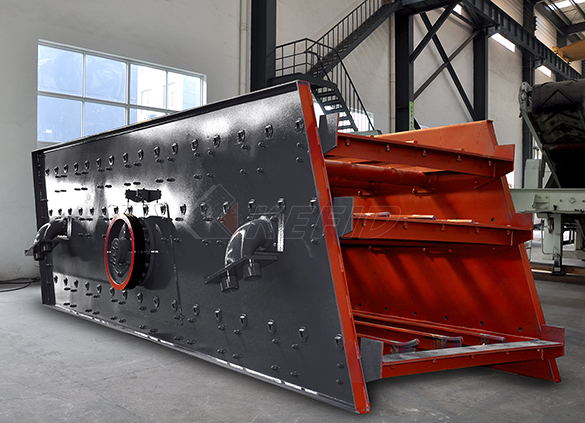

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine