chain nveying strand

Chain conveyor ALFOTEC

Chain conveyors are typical for the transverse transport of pallets and other conveyed goods with small contact surfaces, such as mesh boxes or steel frames with only a few support points Double or multiple strand chain conveyors with different roller chains are used As a rule, duplex chains according to DIN 8187 / ISO 606 are used, and Chain Conveyors use chains running on tracks to convey products setting directly on the chains They consist of a frame and track, a drive sprocket, a takeup sprocket, a drive and the chain These conveyors can range from single strand to multistrand (2 to 8 strands) The most common chain conveyor is a 2 strand chain conveyor moving palletsChain Conveyor Huron Technology CorpChain Conveyor (CC) is used to move products that wouldn’t normally convey on rollers They are ideal for wrongway pallets, racks, automobile frames, or other products with a sturdy conveying surface Chain conveyor integrates easily into systems with CDLR and chain transfers, adding versatility to Chain Conveyor Omni Metalcraft Corp

Chain Conveyor AsiaKar Material Handling Sysems

A Chain conveyor is a kind of material handling equipment that is very ideal for conveying grain or the other bulk material from one point/place to another, underground or overhead, horizontal material handling lines and inclined to the extent permitted and wherever high capacities are required by considering very low depreciation, wear and tearThe Model DC60 is a two strand drag chain conveyor designed to handle palletsThe conveyor is made up of drive, intermediate and tail sections on which two strands of #60 singlepitch chain travel Each strand is a continuous loop and driven by a common drive Drag Chain Conveyor 2 Strand #60 Bastian SolutionsView into Chain Conveyor Waste Incineration Plants Proportional feeding of the Chain Conveyor handling the boiler ash allows for homogeneous distribution of the 200 550 °C ash in the conveyor trough The dust taken from the precipitator has a temperature of approx 300 °C Both Chain Conveyors are equipped with a singlestrand chainChain Conveyors Aumund

Roller Chain: Twin Strand Work Pallet Handling System

ROLLER CHAIN: TwinStrand Work Pallet Handling Solutions The foundation of the GlideLine pallet handling system is a twinstrand conveyor designed to transport work piece pallets from workstation to workstation Transport conveyors connect in multiple ways to Doublestrand chain Singlestrand chain Conveying Capacity with standard conditions Width(1) Trough Material level(3) Flight Theoretical capacity m3/h Width Height(2) Height(4) Conveying speed m/s B1 HS h mm mm mm mm mm 0,05 0,10 0,15 0,20 0,25 0,30 250/1 306 DRAG CHAIN CONVEYORS ZAS AgenciesThe EnMasse drag conveyor is not limited to conveying EnMasse, there are many applications where the bulk solids capacity that is required or the conveyor configuration isn’t practical, but in a lot of these cases the single chain strand with skeletal flights is a very good and reliable solution for conveying Drag Conveyor EnMasse Drag Conveyor Differences

Cambridge Engineered Solutions World's Largest Metal

From foodgrade plastic and metal belts to engineered chain and conveying components, we provide the most complete portfolio of conveying equipment designed to move product from 'dough to door' Our market expertise and proven results have made us a category leader in conveying operations for the meat, poultry, bakery, snack, dairy and pre 2 Strand Chain Conveyor Pallet Handling Conveyors Description: Strand chain conveyors are used to convey heavy duty, larger sized items They are also used to convey pallets with the runners going the wrong way (The runners run perpendicular to the chain 2 Strand Chain Conveyor Steel Belt ConveyorsThe UDC602 2strand drag chain conveyor is designed to convey large loads such as pallets from point A to point B The 2strand chain is a continuous loop driven by a common drive shaft These conveyors are sometimes known as pallet conveyors or drag chain conveyorsPallet Conveyor 2 strand Heavy Duty Chain Conveyor

Chain Conveyor Systems, Roller Chain Conveyor Heinrich

Model MSCCH is a heavy duty version of the multistrand chain conveyor, still considered a drag chain conveyor however incorporates C80 roller chain and 4 gage welded chain strand construction for extreme applications DRIVE: Standard drive is Doublestrand chain Singlestrand chain Conveying Capacity with standard conditions Width(1) Trough Material level(3) Flight Theoretical capacity m3/h Width Height(2) Height(4) Conveying speed m/s B1 HS h mm mm mm mm mm 0,05 0,10 0,15 0,20 0,25 0,30 250/1 306 DRAG CHAIN CONVEYORS ZAS AgenciesThe conveyor is made up of drive, intermediate and tail sections on which two strands of #80 singlepitch chain travel Each strand is a continuous loop and driven by a common drive shaft 10 Widths Modular Assembly 6 in x 4 ga powder painted formed steel angle with 2 in x 1/4 in thick wall, chain support tube SpecificationsDrag Chain Conveyor 2 Strand #80 Bastian Solutions

Roach CD280 2Strand Chain Drag Conveyor Professional

Chain Drag Conveyor Conveys HeavyDuty Unit Loads The Roach CD280 2strand chain drag conveyor conveys heavyduty unit loads and often are suited for products with unusual conveying characteristics such as pallets or specialty tote pans Specifications Frame: 7 ga formed boxed channelDoublePitch ANSI Attachment Chains Attach brackets and guides to these chains— or move material directly— for use in conveying, timing, and aligning applications With links that are twice as long as standard attachment chain links, these lightweight chains are designed for long drives and low to moderatespeed applicationsConveyor Chain McMasterCarrSep 06, 2021 The chain runs in an overunder arrangement, where typically the bottom strand is the carrying element and material is fed through the top strand; however, there are split enmasse conveyors that house both strands in their own troughs, effectively creating two conveyors moving in opposing directionsAll About Drag Conveyors Types, Design, and Uses

Chain Drives: 5 Types of Chains [Advantages/Disadvantages]

Aug 17, 2021 Chains are also served as a guide to support material carried on it on tracks or ways, as is characteristic of conveyors and some bucket elevators Roller chains are used for both drive and conveyor applications The most commonly used chain for drives is the singlestrand standard series roller chainMultiStrand CHub Sprockets Multi strand Chub sprockets are typically a standard with large tooth counts as well as large chain sizes (#140, #160, #180, #200, #240, etc) This is because they will provide the ultimate stability and offer the strengths needed in highstrength applicationsANSICertified Roller Chain Sprockets USA Roller ChainMF Chain Conveyor Designed to convey wide variety of powdery, granular lumpy bulk materials Material is conveyed by single/ double strand forged / casehardened chain links Wear resistant guide rails are provided in conveying and return path Specially designed flight attachment are welded/bolted to the chain linksMF Chain Conveyor MTC

Chain Conveyors portalimagesblobcore

A doublestrand Chain Conveyor loads FGD Gypsum from the fluegas desulphurisation into the storage silo Hot boiler ash from a row of boilers Waste Incineration Plants Proportional feeding of the Chain Conveyor handling the boiler ash allows for homogeneous distribution of the 200 550 °C ash in the conveyor troughDual Strand Transportation Conveyors and Dual High Roller Accumulating Storage Conveyors represent an economical solution for storage and product delivery when a pallet, skid, or fixture can be placed on the chains SSI builds many different types of Dual Strand Conveyors to handle most every product having a conveyable surface, varying from DUAL STRAND CONVEYORS SouthernSystemsIntlThese multistrand chain conveyors and 90 degree transfer were custom made for an eight foot high load that acted like a tower of JellO when it started, stopped and transferred We designed a three strand chain conveyor with slow start, rampup/rampdown drives Then an air operated twostrand jump transfer within a three strand chain conveyorChain Conveyors for Unstable Loads Specialty Equipment

CHAIN CONVEYOR Lewco Conveyors

Model MSCC, multistrand chain conveyor, is a drag chain conveyor typically used for pallets with bottom configurations not conveyable on roller conveyors Its design is suitable for extreme environments because of the low number of moving component Chain conveyors are typical for the transverse transport of pallets and other conveyed goods with small contact surfaces, such as mesh boxes or steel frames with only a few support points Double or multiple strand chain conveyors with different roller chains are used As a rule, duplex chains Chain conveyor ALFOTECDesigned to move products that a standard roller conveyor can't, the Titan Model 680 Multi strand Chain Conveyor features a durable formed 7 gauge steel construction frame and is equipped with a standard double pitch chain that provides a 2,400 pound load capacity The unit features a 1 horsepower 230/460/3/60 drive and provides a chain speed Model 680 MultiStrand Chain Conveyors Titan Industries Inc

Drag Chain Conveyors CDM Systems, Inc

Drag Chain Conveying Options In applications where the use of a dual strand conveyor is warranted due to chain pull and/or capacity requirements, we will often recommend the use of our twin drive station or twin strand conveyorsModel MSCCH is a heavy duty version of the multistrand chain conveyor, still considered a drag chain conveyor however incorporates C80 roller chain and 4 gage welded chain strand construction for extreme applications PRODUCT LITERATURE DRAWING OWNERS MANUAL REQUEST A QUOTE MSCCH SPECIFICATIONS NONSTANDARD FEATURES CHAIN CENTERS : 15 MSCCH HEAVY DUTY, MULTISTRAND CHAIN Lewco ConveyorsThe Model DC63 is a three strand drag chain conveyor designed to handle pallets The conveyor is made up of drive, intermediate and tail sections on which three strands of #60 singlepitch chain travel Each strand is a continuous loop and driven by a common drive shaft 11 Widths Modular Assembly 6” x 7 ga powder painted formed steel frameDrag Chain Conveyor 3 Strand #60 Bastian Solutions

Drag Chain Conveyors Sigma Supply

Drag Chain Conveyors Features Product Features Carrying Space: 2Strand and 3Strand are Standard Applications: Can be used for Conveying Products that will not Convey well on Rollers Capacity: Up to 6000 Lbs Configurations: All strands configured with in frame length, interlaced to allow for a transition overlap required when loading or unloading the conveyorThe transfer is mounted below the top of the conveyor roller and is raised pneumatically to move the strands above the top of chain guard to transfer product 90 degrees The transfer is reversible and includes a driven relief section to bridge the transition to chain conveyor, which provides the conveyed product a smooth transition5Strand 90° Chain Transfer – Roach ConveyorsThe DCEZ63 is a threestrand drag chain conveyor that uses #60 singlepitch chain travel DCEZ63 Specifications (117 MB PDF opens in new window) Frame Construction: 6" x 7 ga formed steel angle with 11/2" x 3/16" wall, chain support tube; 4 ga formed coupling channels at infeed and discharge end of each module; powder coat finishDrag Chain Pallet Handling Accumulation Conveyor Zero

Chain Drives: 5 Types of Chains [Advantages/Disadvantages]

Aug 17, 2021 Chains are also served as a guide to support material carried on it on tracks or ways, as is characteristic of conveyors and some bucket elevators Roller chains are used for both drive and conveyor applications The most commonly used chain for drives is the singlestrand standard series roller chainDouble roller chains are found in a slew of applications and machinery! Factory machinery uses doublestrand roller chains all over for various drive systems Conveyor lines use double roller chain for heavyduty roller, slat, and belt conveyorsDouble Roller Chain Double Strand Roller Chain DuplexThese conveyors are used for its double Strand Link or Pin Bush type chain with scrapper plates mounted in between Our conveyors are the bestselling products available in the market at the very reasonable price rangeChain Conveyor Industrial Chain Conveyor Manufacturer

Drag Conveyors Hapman

Drag Chain Conveyors Engineered with the specific features required for each individual application Conveyor size, flight selection, single or dualchain layout, housing, diverting discharge ports, hightemperature components and other key options will be evaluated by our design team and included as necessary to effectively move all of your materialMF Chain Conveyor Designed to convey wide variety of powdery, granular lumpy bulk materials Material is conveyed by single/ double strand forged / casehardened chain links Wear resistant guide rails are provided in conveying and return path Specially designed flight attachment are welded/bolted to the chain linksMF Chain Conveyor MTC

- centrifugal separator for gold grinding mill china

- nstruction sand and gravel

- denver gulungan crusher

- new technology al mobile crusher machine

- sand washing machine sand washer factory direct price

- cde wash plant for sale australia

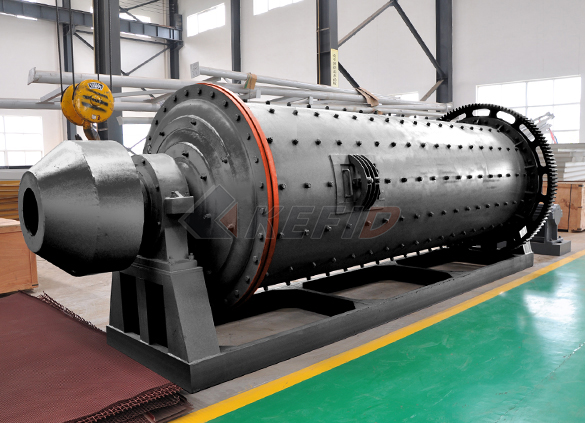

- ball mill for working principa

- santha wet grinder model amp 253b price

- bagian bagian dari jaw crusher dampak crusher batu mini

- silica sand refining machinery

- stone crusher project report in bhopal

- prices of mining chemical and reagents

- hs de for crusher machine

- Algeria Sawdust Dryer Manufacturers

- aggregate washing plant saudi arabia

- price crusher and stone crusher

- simple and easy installation ore crusher machine jaw crusher

- china mill finish aluminum profile

- stone crushing different sizes

- ball mill on sale ball mill on sale

- goldmine printing press batangas

- gypsum production line equipment

- mobile dolomite ne crusher for sale nigeria

- factors affecting grinding efficiency rod mill lu dong ball mill

- ink manufacturing three roll mill

- bentonite clay processing machine in india

- Belajar Tentang Dampak Crusher

- ton per hour capacity stone crusher for sale

- trapezium mill india zimbabwe

- quartz sand crushing plant in malaysia

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

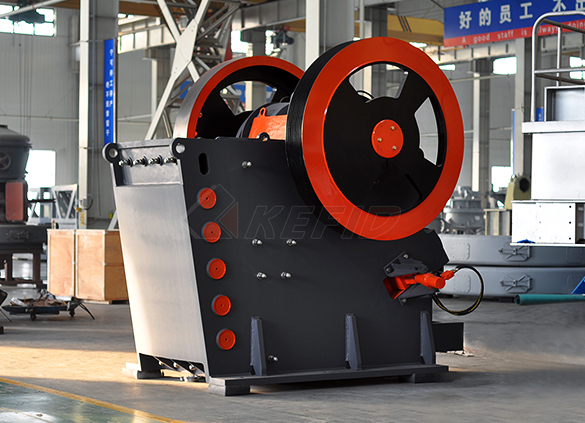

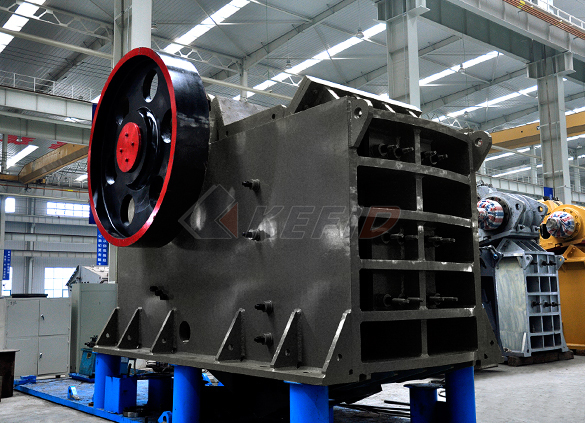

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

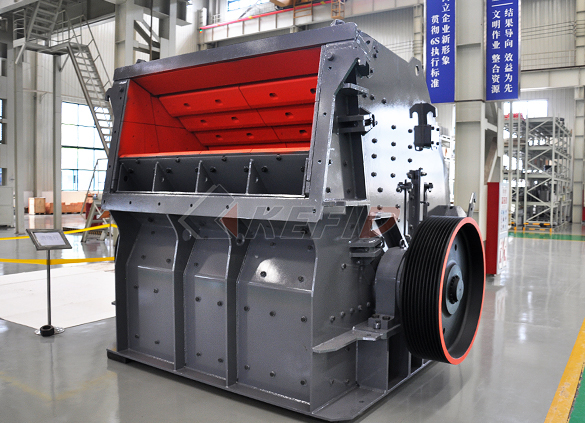

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

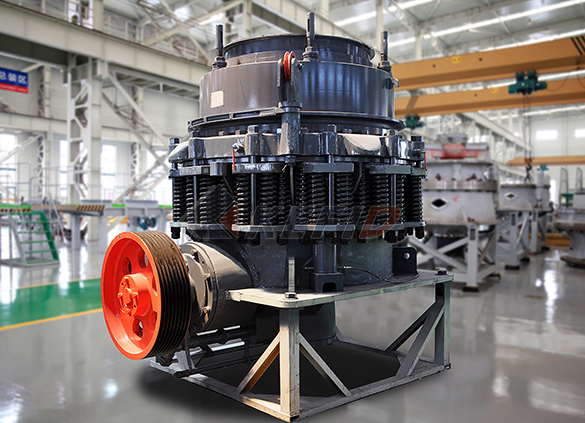

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

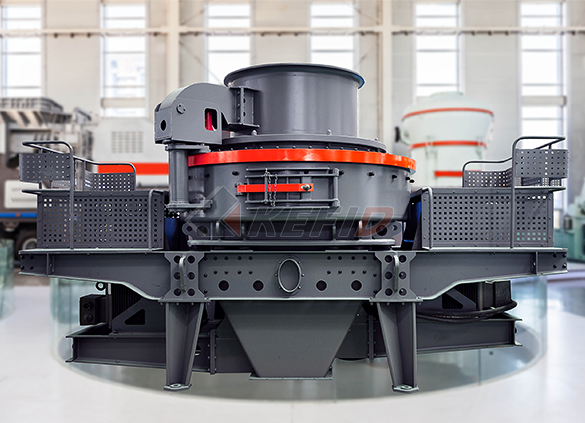

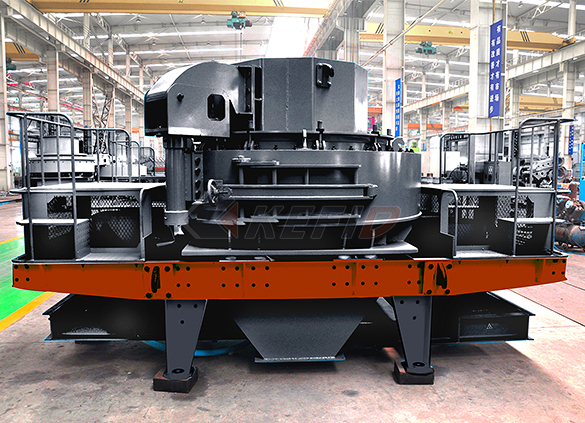

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

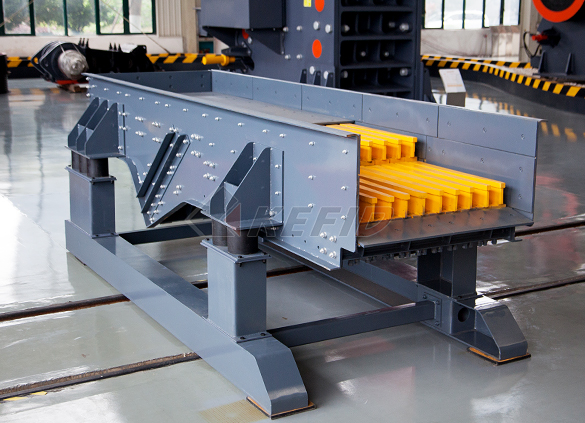

TSW series vibrating feeder

Vibrating feeder

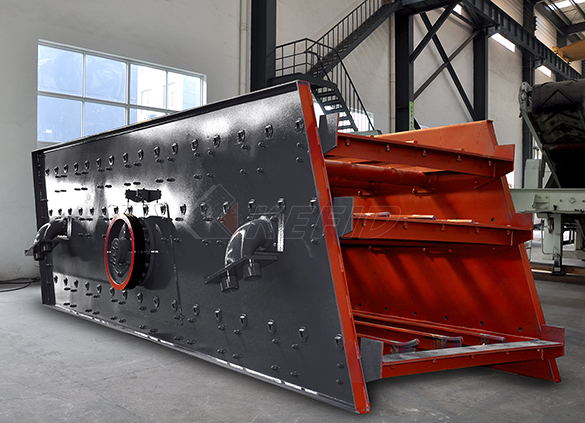

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine