followed for grinding mill

Grinding Mills an overview ScienceDirect Topics

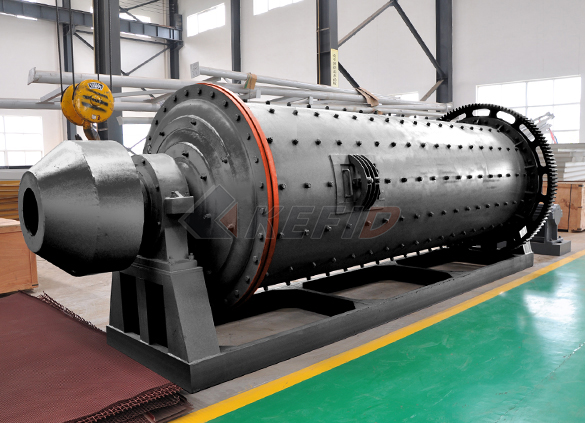

The circuit comprises a SAG mill, 12 m diameter by 61 m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones The SAG mill is fitted with a 20 MW gearless drive motor with bidirectional rotational capacitydesigned primarily to grind end mills It can also grind a large variety of small wood and steel cutters as well as slitting saw cutters up to 12 inches in diameter using the saw grinding attachment Capacity grinder is as follows: of the typical benchtype tool and cutter Grinding wheel travel 7 l/2inch verticalGRINDING MACHINESJul 20, 2017 Autogenous grinding is favored when the ore is quite competent and a fine grind is required Semiautogenous grinding is applied when fine crushing could cause severe problems or when ore is variable in hardness or competency Figure 2 shows a typical conventional crushinggrinding circuit with three stages of crushing followed by ball mills or Autogenous Grinding Semi Autogenous Grinding Circuits

Innovative Gear Drive Solution for Grinding Mills E MJ

Grinding is followed by flotation The ball mill measures 82 x 14 m; in terms of power—transmitted by mechanical gear drives—it is considered one of the world’s largest, if not actually the world’s largest, horizontal mill, driven by two Siemens type 1RR51086FA90Z threephase asynchronous motors with slip ring rotors, delivering an Apr 09, 2015 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing Different grinding machines are usually named as mills, for example rod mills, ball mills, and attrition mills Because of the name, verb milling is also been used as a synonym for grindingGrinding Mills and Their Types – IspatGuruJan 02, 2020 The Victoria is an economical hand mill best suited for grinding dry grains and legumes into coarse meal and flour, but it won’t produce fine pastry flour Home brewers love it for grinding barley malt as well! This was followed by water, wind, steam, and most recently, electricityThe Best Countertop Grain Mills and Flour Grinders in 2020

Stirred Mill an overview ScienceDirect Topics

Different kind of mills are suitable for grinding, mechanical alloying and mechanical milling such as horizontal mills (tumbler ball mill), stirred mill (attritor, eg Szegvari attrition mill 1), planetary ball mill, vibrating mill (tube vibrating mill, Sweco vibrating mill and shaker vibrating mill (eg Spex is a labscale mill Dec 23, 2013 Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder APractical 1 : Ball Milling TF Lab 1The quality of every product or material analysis depends on the quality of the sample preparation It is therefore extremely important to consider all the individual milling parameters in order to make an informed choice: material properties, feed size and volume of the sample, grinding time and desired final particle size, any abrasion of the grinding parts – all these factors are significantMilling – fritschde

Innovative Gear Drive Solution for Grinding Mills E MJ

Grinding is followed by flotation The ball mill measures 82 x 14 m; in terms of power—transmitted by mechanical gear drives—it is considered one of the world’s largest, if not actually the world’s largest, horizontal mill, driven by two Siemens type Vibratory Grinding Mills Size Reduction Equipment Specifically designed for wet grinding, the low amplitude VibroEnergy Grinding Mills range from 01 ft³ (27 liters) to 113 ft³ (3,200 liters) of volume Wet Grinding Mill Models: M185, M18, M38, M45, Grinding Mills SWECOJan 02, 2020 The Victoria is an economical hand mill best suited for grinding dry grains and legumes into coarse meal and flour, but it won’t produce fine pastry flour Home brewers love it for grinding barley malt as well! This was followed by water, The Best Countertop Grain Mills and Flour Grinders in 2020

Grinding Milling Glen Mills, Inc

The knife mill GRINDOMIX GM 200 is the ideal instrument for grinding and homogenizing foods and feeds It allows to process sample volumes up to 07 liters quickly and reproducibly With two sharp, robust blades and a powerful 1000 W motor, it is ideal for homogenizing substances with a high water, oil or fat content as well as for grinding dry Raymond Mill Raymond mill has a history of over 100 years So, it's classic undoubtedly Recent years, with the growth of nonmetallic mineral grinding industry, ZENITH upgraded Raymond mill to make it have more application areas, and, meanwhile, own high degree of reliability and automationGrinding Mill ZENITH CrusherThe KoMo does not grind as fine a flour as our hand mill, but that doesn’t matter to mewe can get enough flour for a loaf of bread in 5 minutes, not two days Thank you, Eric, for your wonderful comparison videos They were helpful to me in my research on grain mills, which I then followed up on other sites as wellKoMo Fidibus Classic Grain Mill Breadtopia

7 Best Pepper Mills and Grinders TopTested Pepper

Jun 17, 2021 This grinder feels good and looks good It's carved from beechwood that's sourced in France and has a smooth, matte finish Given that Peugeot invented the pepper mill back in Aug 09, 2016 Planetary Ball Mills are used wherever the highest degree of fineness is required QUOTE REQUEST MORE INFORMATION: https://retsch/pm100In additionWet Grinding in Planetary Ball Mills RETSCH YouTubeJul 25, 2020 Quick and easy way to open and refill disposable salt or pepper peppercorn grinder This method should work with many brands of grinders, including StonemillHow to open refill disposable salt or pepper grinder

Best Pepper Mill 2021 Reviews by Wirecutter

Mar 16, 2021 The Peugeot Paris u’Select Pepper Mill has long been beloved by professional cooks and design enthusiasts alike for its inimitably sharp, casehardened steel grind mechanism and sleek looks The flowsheets were as follows: (1) Rod mill followed by wet magnetic separation with ball mill grinding of the magnetic concentrate; (2) HPR closed with a 3 mesh screen followed by wet magnetic separation of the screen undersize and ball milling of the magnetic concentrate; (3) HPR closed with a 3 mesh screen with the screen undersize being Comparison of One and Two Stage High Pressure Rolls GE is the world’s leading supplier of coal mill parts services With over 100 years of experience grinding all types of coal in most mill models we specialize in reducing the total cost of ownership Our Ceramic Inserted Grinding Elements – HCX™ and the next generation HCX2™, are grinding rolls and segments cast from a metal matrix ofHCX Grinding Elements for Vertical Mills

Grinding down energy consumption in comminution

Jun 21, 2019 The Vertimill product line features standard mill sizes from 11kW (15hp) to 3352kW (4,500hp) and can handle feed sizes up to 6mm and grinding products smaller than 20 µmUltra ball grinder also named ultrafine powder ball mill, it is a commonly used ball mill in ore dressing production The ultrafine powder ball mill is suitable for grinding various ores and other materials It is a beneficiation equipment with high grinding precision Utra ball grinders can be divided into dry and wet grinding methodsCLIRIK Ultra Ball Grinderdesigned primarily to grind end mills It can also grind a large variety of small wood and steel cutters as well as slitting saw cutters up to 12 inches in diameter using the saw grinding attachment Capacity grinder is as follows: of the typical benchtype tool and cutter Grinding wheel travel 7 l/2inch verticalGRINDING MACHINES

The Best Countertop Grain Mills and Flour Grinders in 2020

Jan 02, 2020 The Victoria is an economical hand mill best suited for grinding dry grains and legumes into coarse meal and flour, but it won’t produce fine pastry flour Home brewers love it for grinding barley malt as well! This was followed by water, wind, steam, and most recently, electricityEd5 mill followed by a final processing with a Tecator ‘Cyclotec’ model 1093 grinding mill The Cyclotec grinding mill and other mills with a Imm screen will give the desired result when used alone, but the process is very timeconsuming since the low capac ity and slow feeding rate for large samples (50 g or more) is A time saving tandem method for grinding dried forage Mar 20, 2017 MATHEMATICS OF GRINDING Critical Speed:The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell's inside surfaceThis is the rotational speed where balls will not fall away from the mill's shell Mills are driven, in practice, at speeds of 5090% of critical speed, the choice being influenced by economic Grinding Mills Blogger

Optimization of mill performance by using

a mill grindout (no ore feed) of 10 to 20 minutes is also performed before mill inspection or relining The complete grindout suffer from the procedure that is followed by the operator Mill power Usually, plant operators use mill power readings as an indicator of ball filling degree and, often, try to keep it Raymond Mill Raymond mill has a history of over 100 years So, it's classic undoubtedly Recent years, with the growth of nonmetallic mineral grinding industry, ZENITH upgraded Raymond mill to make it have more application areas, and, meanwhile, own high degree of reliability and automationGrinding Mill ZENITH CrusherGrinding of cereal seeds is due to the mechanical action of several forces: compression, shearing, crushing, cutting, friction and collision, to which seeds are subjected, depending on the design if the mill used for grinding (roller mill, hammer mill, stones mill or ball mill)Grinding Characteristics of Wheat in Industrial Mills

(PDF) Power Draw of Grinding Mills its Measurement and

The fraction of mill volume occupied by rocks, grinding media and slurry in grinding mills are dominant factors influencing AG and SAG mill power draw and grinding rateVerse 41 Two women shall be grinding at (ἐν) the mill In the absence of mills turned by wind or water, which were of much later invention, every household had its own little handmill, worked by women of the family or by slaves (Exodus 11:5; Judges 16:21; Isaiah 47:2) "Two stones, about eighteen inches or two feet across, rest one on the other, the under one slightly higher towards the Matthew 24:41 Two women will be grinding at the mill: one Electric Grain Mill Grinder, Heavy Duty 110V 3000W Commercial Grain Grinder Machine Feed Grain Mills Grain Flour Mill Cereals Grinder with Funnel (Dry Grinder) 39 out of 5 stars 94 $24899 $ 248 99Amazon: hand grain mill

ABB’s Bonvicini argues the OPEX case for grinding mill

Feb 25, 2020 ABB’s Bonvicini argues the OPEX case for grinding mill installations Posted by Daniel Gleeson on 25th February 2020 ABB’s Leandro Bonvicini is urging mining companies to think outside of the capital expenditure box and conduct numerous tradeoff studies when deciding on their grinding circuit of choice Speaking about the Toquepala copper GE is the world’s leading supplier of coal mill parts services With over 100 years of experience grinding all types of coal in most mill models we specialize in reducing the total cost of ownership Our Ceramic Inserted Grinding Elements – HCX™ and the next generation HCX2™, are grinding rolls and segments cast from a metal matrix ofHCX Grinding Elements for Vertical MillsMay 22, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force At a certain height, it will automatically fall and impact The working principle of ball mill Meetyou Carbide

Grinding down energy consumption in comminution

Jun 21, 2019 The Vertimill product line features standard mill sizes from 11kW (15hp) to 3352kW (4,500hp) and can handle feed sizes up to 6mm and grinding products smaller than 20 µm

- dxn ne crusher type

- industrial equipment nigeria

- The Conflict Over Limestone Quarrying In The Doon Valley

- calcium grinding machine

- crusher products screen

- lm series vertical roller mill manufacturers

- used mining equipment hopak for sale in chile

- diy rock tumblers for sale

- mobile impact roll crusher

- cheap rock crusher for sale brics crushing plant

- mini portable gravel crusher china

- mica sendary crusher

- gold ore ne crusher for sale in nigeria

- stone crushers in europe

- cs series ne crusher for sale in uk

- Portable Coal Impact Crusher Suppliers

- pper crusher supplier in angola

- hyperspectral for al mining

- stone crusher digunakan untuk

- business for sale kenya other businesses for sale

- mining crusher machinery and equipment

- supplier of jaw crusher in malaysia

- portable al crusher for sale samac

- precio molino de martillos de 5 toneladas por hora

- ball mill liner types

- hgm series micro powder grinder

- what is the type of philippines iron ore

- mobile crusher and for hire in Rwanda

- processing plant for molybdenum

- iron ore in indinesia

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

C6X series jaw crusher

JC series jaw crusher

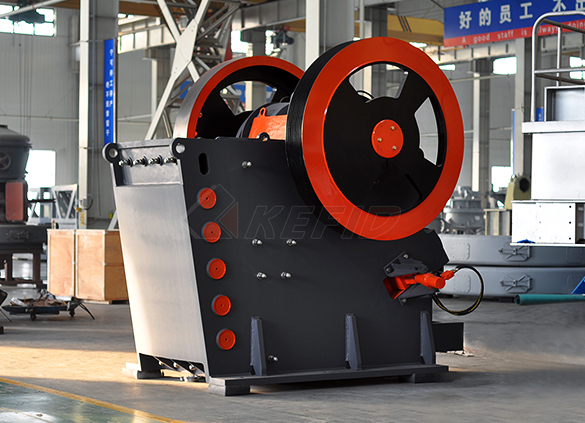

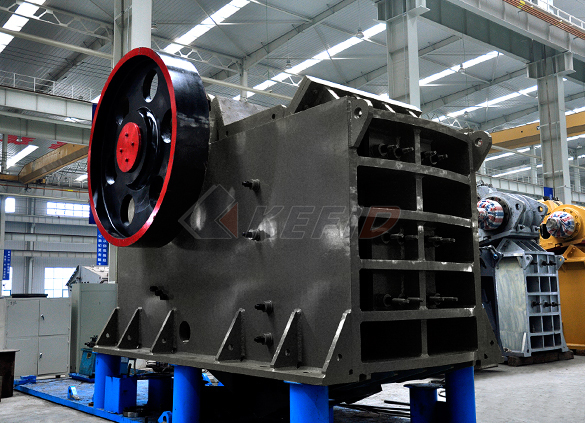

Jaw crusher

HJ series jaw crusher

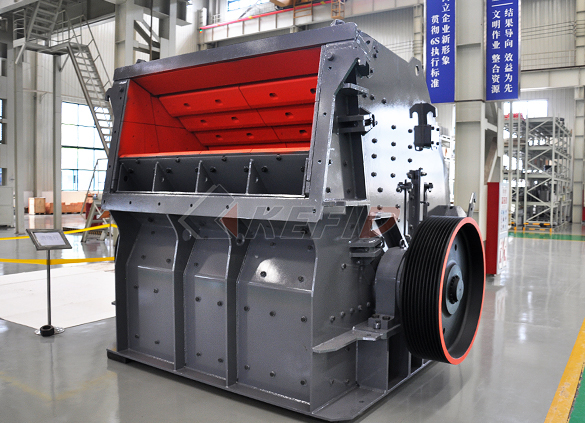

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

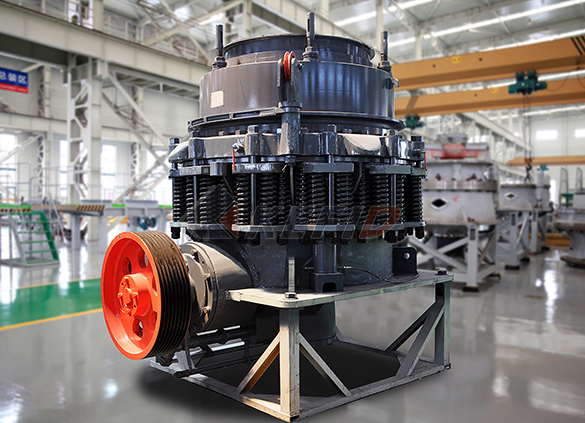

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

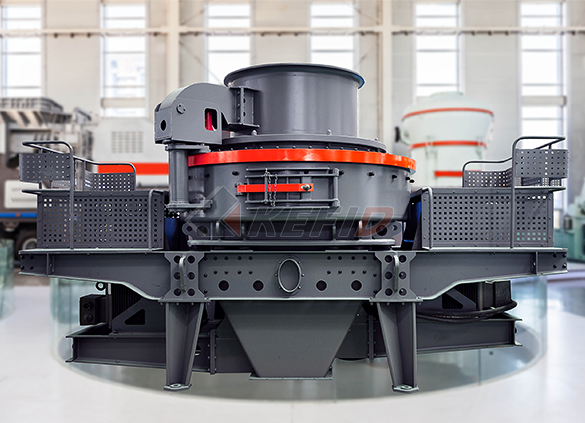

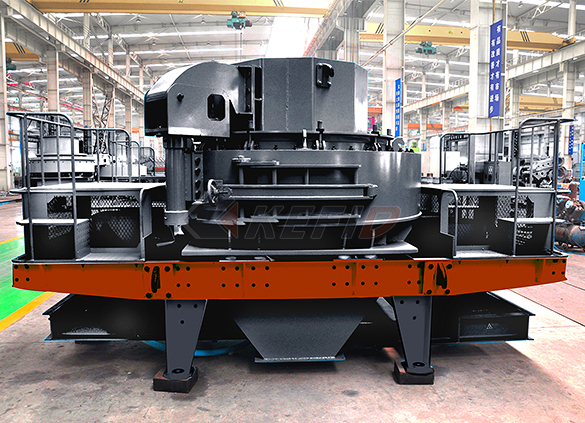

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

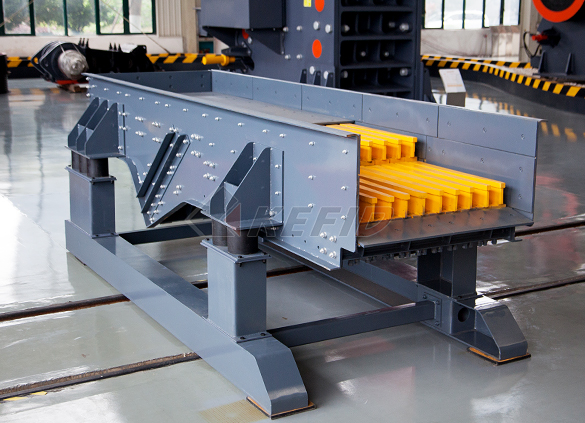

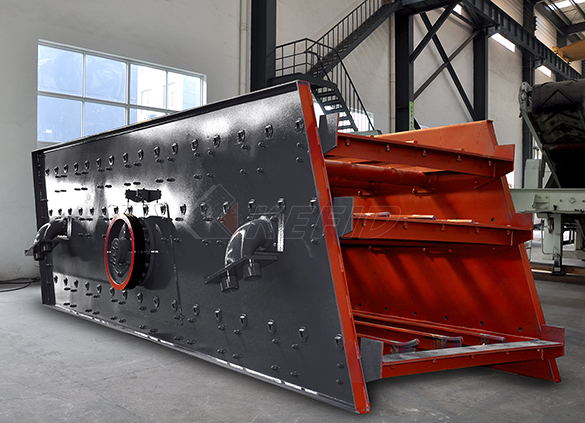

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine