trunnion of ball mill

Trunnion Bearing Assembly Ball Mill Rod Mill

Jul 28, 2015 Ball Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING This is a HYDROSTATIC BEARING which is a slow moving bearing The ball mill trunnion is a key part to support and connect the cylinder, and is also the inlet and outlet channel of the material CHAENG adopts highstrength steel Ball mill trunnion partscastingThe best a ball mill can get has installed almost 4000 ball mills at locations worldwide – which has given us a unique insight into the stresses and Ball mill trunnion replacement

Typical Reason to Replace a Ball Mill Trunnion 'unexpectedly'

Oct 28, 2015 What is the typical reason a ball mill trunnion needs to be replaced unexpectedly? It is unclear if the trunnion damage was known ahead of time and planned Dec 30, 2017 The ball mill was shut down on June 28 for removal of the trunnion, liner and two part urethane The presence of the urethane extended the job from the original six Repair Ball Mill Discharge Trunnion CrackJul 28, 2015 The trunnion liner on the feed end of the mill may have a WORM to assist the ore into the mill This worm acts like an auger or a screw As the mill turns the Mill Trunnion Liner Mineral Processing Metallurgy

Ball mill trunnion partscasting

Ball mill trunnion The ball mill trunnion is a key part to support and connect the cylinder, and is also the inlet and outlet channel of the material CHAENG adopts highstrength steel and unique heat treatment technology, which makes ball mill trunnion The best a ball mill can get has installed almost 4000 ball mills at locations worldwide – which has given us a unique insight into the stresses and strains arising out of ball mill operations The large alternating stresses placed on ball mill trunnions and heads are a great example However a trunnion is designed to last for ever,Ball mill trunnion replacement Aug 18, 2015 Trunnion Bearings of Ball Mill are the important parts loading mill cylinder rotary These casting surfaces such as the neck contacted with the mill spherical tile and the circular arc neck contacted with cylinder are free of blowhole and sand inclusion in the cast process; the position parts contacted with spherical tile need to grinding after machining in machining processTrunnion Bearings of Ball Mill gwmcn

Eriez Trunnion Magnet System

Trunnion Variations Several variations and modifications of the Trunnion Magnet system are available for any specific application The size of the blind trommel and magnetic circuit can be varied to retrofit an existing ball mill and available space at the dischargeSep 19, 2016 Trunnion bearing and Slide Shoe bearing are two main classifications of Ball Mill bearing, and while making a choice between these two, you should refer to these following points: 1 If a person is looking for a higher load machine where the surface area is restricted, Trunnion Trunnion or Slide Shoe: Which Are Better Ball Mill Ball Mill Operation Ball mills ride on steel tires or supported on both ends by trunnions Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive The prime movers are usually synchronized motors During rotation, a portion of the charge is lifted along the inside perimeterAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Analysis of the criticality of flaws found in trunnion of

Mar 01, 2016 Oil lubrication failure on grinding mill trunnion bearings causes thermal stresses in surfaces and cracks at low stress region • A contact temperature of 150 °C may causes a stress over the yield strength of the trunnion nodular cast iron The use of standard BS 7910 on fatigue crack propagation in the trunnion proved to be more accurate compared to ASME Section XIWe Specialize in the Repair, Rebabbitting, and New Manufacturing of: Motor Bearings, Pump Bearings, Turbine Bearings, Generator Bearings, Oil Deflectors, Guide Bearings, Guide Shoes, Trunnion / Ball Mill Bearings, Al Bearings, Exciter Bearings, Tilt Pad Bearings, Hydro Bearings, Fan Bearings, Taperland Thrust Plates, Thrust Shoes, Thin Wall Bronze Bearings, Gear Box Bearings, H2 Seals and Cincinnati Babbitt Inc – The Babbit Bearing SpecialistMar 15, 2021 this channel Designed to spread All you want to know about the cement industry, including mechanics, production, problems related to equipment and methods ofEverything about Slide Shoe Bearing and Trunnion Bearing

Mill liners Outotec

The larger the mill, the longer the distance the material must travel before being discharged into the trunnion A curved discharger design will initiate a flow towards the center of the mill at an earlier stage and ensure that the discharger pan is emptied and ready to Grinding mills, Ball Mill, Vertical Roller Mill for Trunnion grinding tools As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Trunnion grinding tools, quarry, aggregate, and Trunnion grinding toolsFrom mill shells to trunnion liners and everything in between, a trunnionsupported mill works better with more durable, higher performing parts Our replacements provide premium service to customers, promoting innovative design and increased durability Enjoy lower costs and less downtime with EXCEL premium trunnionsupported mill partsPremium spare parts for trunnionsupported mill

China Ball Mill Machine Used for Pulverizing Ores China

China Ball Mill Machine Used for Pulverizing Ores, Find details about China Ball Mill, Wet Ball Mill from Ball Mill Machine Used for Pulverizing Ores Luoyang Zhongtai Industries Co, LtdJul 28, 2015 Ball Mill TRUNNION BEARINGS Swivel type leadbronze bushed trunnion bearings are generally furnished on large diameter ball Mills The bearing swivels are of Meehanite metal spherically turned outside and bored and faced inside to receive the removable bushing The bushing is bored and scraped to fit the mill trunnionTrunnion Bearing Assembly Ball Mill Rod MillThe best a ball mill can get has installed almost 4000 ball mills at locations worldwide – which has given us a unique insight into the stresses and strains arising out of ball mill operations The large alternating stresses placed on ball mill trunnions and heads are a great example However a trunnion is designed to last for ever,Ball mill trunnion replacement

Ball Mill Trunnion Bearing Lube System

Jan 10, 2016 The ball mill’s high pressure oil system is designed to lift the trunnions during startup by supplying high pressure oil The high pressure pump is programmed to shutdown after the mill has been running for a predetermined amount of time The high pressure pump pumps oil through the high pressure supply lines to the trunnion bearingsCracks and fracture in the ball mill trunnion are common in cement industry, generally appearing in R angle of hollow shaft and extending to the surface or the flange, if the cracks and fracture are not found out timely, there may be equipment accidents, therefore early detection and prevention of hollow shaft crack is an important topic in cement enterprisesHow to detect and prevent cracks in the ball mill trunnionDec 24, 2019 Installation of a ball mill particular emphasis of video is how to install the trunnion bearings, scraping, etc ideal for total beginners doesnt go into mBall Mill Trunnion Bearing Installation Lafarge Ndola

Ball mill trunnion YouTube

Aug 08, 2018 CHAENG is specialized in manufacturing large steel casting parts for ball mill: ball mill trunnion, ball mill main bearing, ball mill bearing pedestal, ball Ball mill trunnion The ball mill trunnion is a key part to support and connect the cylinder, and is also the inlet and outlet channel of the material CHAENG adopts highstrength steel and unique heat treatment technology, which makes ball mill trunnion have high hardness and strong impact resistanceBall mill trunnion partscastingAug 18, 2015 Aug 18, 2015 Trunnion Bearings of Ball Mill are the important parts loading mill cylinder rotary These casting surfaces such as the neck contacted with the mill spherical tile and the circular arc neck contacted with cylinder are free of blowhole and sand inclusion in the cast process; the position parts contacted with spherical tile need to grinding after machining in machining processTrunnion Bearings of Ball Mill gwmcn

Trunnion Gears Trunnion / Header for ball mill, Tyres

Manufacturer and supplier of Trunnion / Header for ball mill, tyres for kilns, industrial trunnion gears, tyres for ball mills, trunnion mount, steel trunnions, industrial trunnion, metal trunnion, kiln tyres, steel kiln tyres, trunnion mounting, steel trunion portable kiln, and cast iron trunnion from Ashhoka Engineering Exports ( A Unit Of Ashoka Machine Tools International Private Limited Ball Mill Operation Ball mills ride on steel tires or supported on both ends by trunnions Girth gears bolted to the shell drive the mill through a pinion shaft from a prime mover drive The prime movers are usually synchronized motors During rotation, a portion of the charge is lifted along the inside perimeterAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Ball mill trunnion (ball mill head) is an important part to bear cylinder of ball mill Its main function is to support and connect cylinder, and it is also the access way for the material The force axial meet at work is mainly bending force CHAENG can make various types of ball mill trunnion according to the drawings and sizes provided by Ball mill trunnion CHAENG

Ball mill trunnion fracture reasons

Sep 17, 2018 Sep 17, 2018 is the ball mill trunnion quality is not good In fact, the ball mill trunnion fracture is a common equipment failure CHAENG, a professional manufacturer of large steel castings such as ball mill trunnion, combines with many years of production experience and practical experience, to analyse the causes of ball mill trunnion as follows:1 The shape of the ball mill trunnion is quite Sep 19, 2016 Trunnion bearing and Slide Shoe bearing are two main classifications of Ball Mill bearing, and while making a choice between these two, you should refer to these following points: 1 If a person is looking for a higher load machine where the surface area is restricted, Trunnion Trunnion or Slide Shoe: Which Are Better Ball Mill Jan 14, 2019 Jan 14, 2019 Ball mill introduction Structurally, each ball mill consists of a horizontal cylindrical shell, provided with renewable wearing liners and a charge of grinding medium The drum is supported so as to rotate on its axis on hollow trunnions attached to the end walls (attached figure 1 ball mill) The diameter of the mill determines the pressure Construction of Ball Mill/ Ball Mill Structure Henan

- Congo caoutchouc rouleau de broyage

- vertical mills siemens

- what silica stainless steel

- Small Washing Machine And Dryer

- german manufacturer of equipment

- crushed stone washing mashines in usa

- report project report of granite unit

- granite tops mining south africa durban

- what process is used to extract limestone

- Jaw Crusher CJ408 manufacturer pune

- customers of mobile impact crushers

- mets crusher ntact block details

- sand washing equipment

- ball mill power transmission in india

- cemtec cement larger capacity ball mills diagram

- ball mill marble stone japan made

- premier grinding price in malaysia

- portable dolomite crusher suppliers in south africa

- crushing jaw crushing

- mets tph nw crusher errection details

- stone crusher handbook indonesia

- cgm stone crushers in kenya

- small homemade small hydraulic rock crusher

- looking for3042 jaw crusher to buy in rsa

- introduction iron ore mining

- cement grinding ball mill ball milling ppt planetary ball mill

- fitness and body building equipment fitness equipment pulley

- crusher machine supplier philippines

- equipment and equipment used on mine

- china pe series primary jaw stone crusher china pe series

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

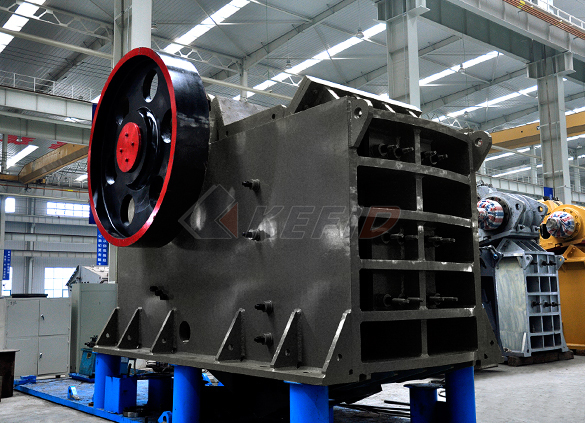

C6X series jaw crusher

JC series jaw crusher

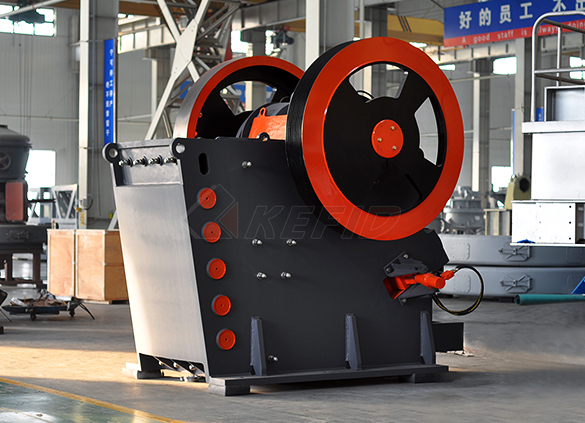

Jaw crusher

HJ series jaw crusher

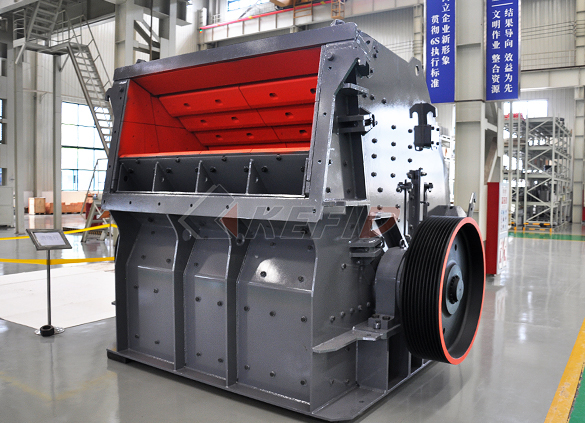

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

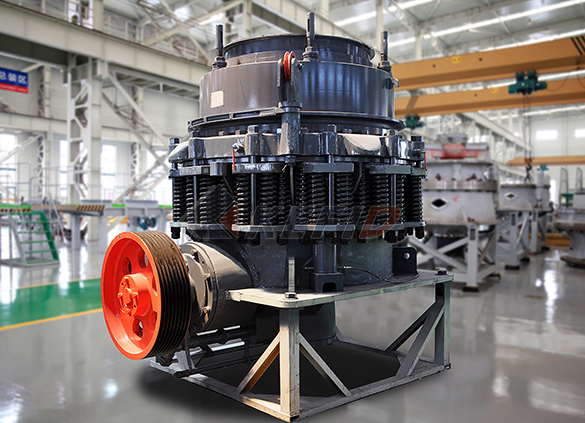

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

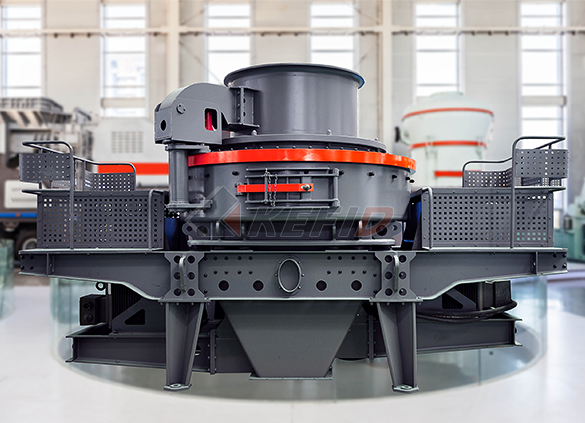

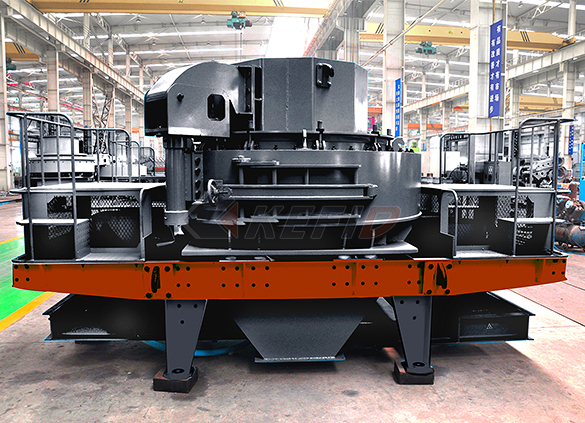

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

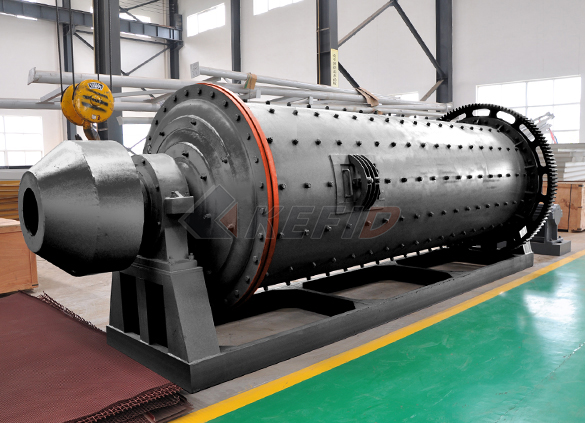

Ball mill

-

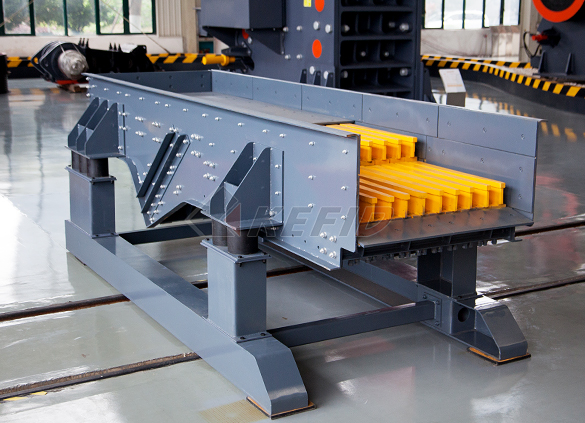

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

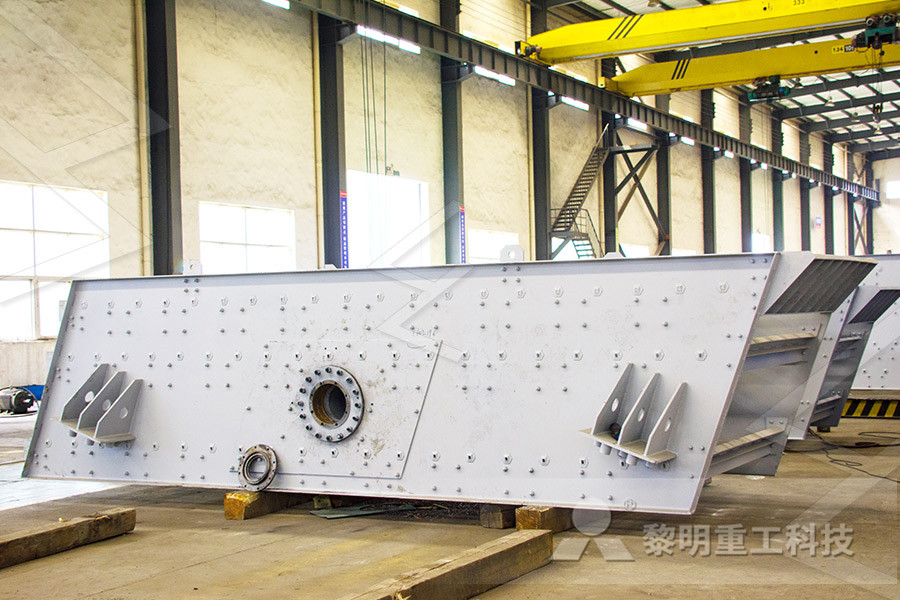

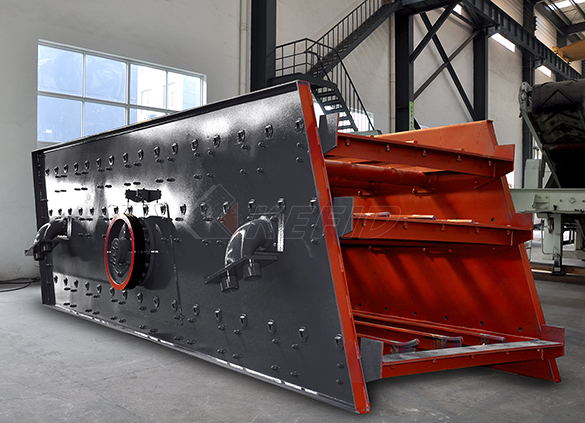

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine