roll mill advantages of ball mill

advantages and disadvantages of ball mill

The advantages and disadvantages of ball mill Roller mill The advantages of ball mill: 1 It can grind different kinds of material, and has large capacity It ground there were stone mills, ball mills and later three roll mills limitations, but every other coating manufacturer used one or the other type of the same The major advantage that ball mills have is that they will eventually make anadvantages and disadvantages of roll millJul 04, 2018 Advantages and disadvantages of vertical roller mill Vertical roller mill (vertical grinding mill) is mainly suitable for ultrafine powder processing of noninflammable and nonexplosive brittle materials with medium and low hardness and Moh’s hardness of 6Advantages and disadvantages of vertical roller mill

Ball mill SlideShare

Apr 24, 2015 5 The ball mill is used for grinding materials such as coal,pigments,and fedspar for pottery Grinding can be carried out in either wet or dry but the former is carried out at low speeds The advantages of wet grinding are less power consumption,increased capacity,no dust formation etcJan 11, 2016 Advantages of Ball Mills 1 It produces very fine powder (particle size less than or equal to 10 microns) 2Ball Mill: Operating principles, components, Uses Feb 28, 2010 In the case of beef lots, where the finished feed is not required to be pelleted for purposes of costeffective transportation, the roller mill can be used quite effectively and can be a key part of reducing power consumption at the millHammermills versus roller mills Worldgrain

disadvantages of ball mill proces

Disadvantages Of Ball Mill Process Krosline The advantages and disadvantages of ball mill roller millhe advantages of ball mill 1t can grind different kinds of material, and has large capacityit is a ball milling process where a powder mixture placed in the ball mill is subjected hase are the other disadvantages of highenergy ball milling processet priceJan 11, 2016 Advantages of Roller Mills 1 Produce more uniform, fewer fines, and oversized particles when it comes to product quality 2Roller Mill: Components, Designs, Uses, Advantages and Jul 03, 2017 Because of this, the rod mill can effectively reduce 1″ feed size to 10 mesh or finer in open circuit The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load Rods in place weigh approximately 400 pounds per cu ft and balls in place approximately 300 pounds per cu ftBall Mills vs Rod Mills

Size Reduction Equipment Paul O Abbé

Benefits of Tumble Milling: HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into milling and less wasted as heat (more)Roller mills simply “roll” or “crush” product between two revolving cylinders This latter process has the distinct advantage of requiring considerably less power, although it is not possible to achieve the fineness of final grind through a roller mill that can be achieved through a hammermillHammermills versus roller mills Worldgrain Size Reduction Tumbling Steel Ball Mills and Ceramic Lined Mills are one of the most precise, reliable and cost effective methods of fine grinding solids in either a wet or dry stateBall Mills are referred to by many names including Pebble Mills, Tube Mills and Attrition Mills, but no matter what the nomenclature they all operate on the same efficient principleSize Reduction Equipment Paul O Abbé

Rod Mills Mineral Processing Metallurgy

May 31, 2016 Hammer mills and rolls are not used that often and then usually only for special applications as in lab work or chemical preparation The type of mill that is used for grinding ore in a modern concentrator is the wet tumbling mill These mills may be divided into three types ROD MILLS, BALL MILLS and AUTOGENOUS MILLSFeb 18, 2019 The vertical roller mill is a grinding equipment that has both the functions of crushing and grinding, and uses the material to be ground to work as a medium The slag vertical mill is similar to the ball mill, but the vertical grinding principle and structure are quite different from those of the ball mill In the following, the vertical mill manufacturer chaeng will analyze the difference Advantages of vertical roller mills compared to ball 42311 Roll Mills The roll mill is the simplest batch mixing equipment The principal design consists of two horizontal rolls, usually of equal size, arranged side by side and rotating toward each other at different speeds The ratio of the peripheral speeds of the rolls, known as friction ratio, ranges from 1 to 2 but is usually around 12Roll Mill an overview ScienceDirect Topics

Using Ball Mills to Extract Raw Gold from Ores

Jun 14, 2018 The Function of a Ball Mill To perform its functions, the ball mill operates on the principle of impact and attrition This principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact The major components of the ball mill include a shell that is hollow and is suspended on its axis Compared with sliding bearing,the rolling bearing of ball mill possesses advantages of low friction factor and force saving etcTherefore,rolling bearing is widely used at ball mill by many manufacturersType selection and matching of rolling bearings of ball millAdvantages of DoubleRoller Crusher 1 In the production, the crushing range of double roll crusher is wide Whether it is coal or large ore, as long as the material with Mohr hardness below 9 can be crushed by this machine 2 The speed of finished products of toothed roll crusher is extremely fastAdvantages and Disadvantages of Roll CrusherThe NIle

Roll Mill Advantage And Disadvantage Of Ball Mill

Advantages and disadvanges, Ball Mill or Roller Mill Advantages and disadvanges, Ball Mill or Roller Mill? Some customers asked us what is the advantage and disadvantage of the two kinds of grinding millssingle pair roller mills; double pair roller mills; triple pair roller mills; quadruple pair roller mills; automation; accugap; gravity scalper; scalper assist; magnets; brewing and distilling brewing solutions main page; brew features; two roller configurations; four roller configurations; six roller configurations; bulk bag system; vertical RMS Roller Grinder RMS Roller GrinderThe difference between vertical roller mill and ball mill The ball mill is generally composed of a horizontal cylinder, a hollow shaft for feeding and discharging, and a grinding head The cylinder body is provided with an abrasive body, the cylinder body is made of steel plate, and the steel lining plate is fixed with the cylinder body, and the grinding body is generally a steel ball, and The difference between vertical roller mill and ball mill

Ball Mill Refining Kocotek

Ball Mill Refining Liquid Conching Chocolate and compound coatings can be produced using distinctly different methods and equipment In addition to conventional roll refining systems (with ‘dry’ conches) Kocotek also specializes in modern ball mill based systems (with ‘wet’ conches) We are also uniquely specialized in ‘hybrid Laboratory roller ball mill Laboratory roller ball mill is a laboratory equipment for small batch production with ultrafnie grinding and mixing The lab roller ball mill has the advantages of beautiful appearance, compact structure, convenient operation, high working effeiciency and fine grain sizeChina Laboratory Roller Ball Mill Manufacturers The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with small Cement Roller Press Roller Press In Cement Plant

Advantages of vertical roller mills compared to ball

Feb 18, 2019 The vertical roller mill is a grinding equipment that has both the functions of crushing and grinding, and uses the material to be ground to work as a medium The slag vertical mill is similar to the ball mill, but the vertical grinding principle and structure are quite different from those of the ball mill In the following, the vertical mill manufacturer chaeng will analyze the difference The advantages of ball mill – Kitchener – Businesses for sale The advantages of Ball Mill is as follows: (1) adaptability is strong, for most materials can be grinding (2) can continuous operation, and production capacity can Advantages Of A Ball Mill Crusher Mills, Cone Crusher Roller Mill Advantage And Disadvantage Of Ball Mill ADVANTAGES AND DISADVANTAGES OF BALL MILL Crusher Mills Ball Mill Get Price; vertical roller mill disadvantages Our vertical roller mill disadvantages Have Exported To South Africa, USA, Australia, Ghana, triple roll mill advantages disadvantages in wikipedia Get Price roller mill advantages and disadvantages

How HPGRs compare to conventional milling

Aug 19, 2019 How HPGRs compare to conventional milling Whether you’re designing a brandnew mill circuit or optimising an existing site for longterm efficiency, High Pressure Grinding Rolls offer a range of advantages over conventional milling techniques, including ball mills, SAG mills and rod millsMay 31, 2016 Hammer mills and rolls are not used that often and then usually only for special applications as in lab work or chemical preparation The type of mill that is used for grinding ore in a modern concentrator is the wet tumbling mill These mills may be divided into three types ROD MILLS, BALL MILLS and AUTOGENOUS MILLSRod Mills Mineral Processing MetallurgyVertical cement mill appears later than cement ball mill, which makes up for many shortcomings of cement ball mill and has more advantages In the past, due to the limitation of cement ball mill production, many cement companies were unable to expand production scale and Vertical Cement Mill ball mills supplier

About the advantages of horizontal planetary ball mill

Apr 23, 2018 The planetary ball mill is equipped with four ball mill jars on the same turntable When the turntable rotates, the ball mill jar orbits around the axis of the turntable and rotates around its own axis to perform planetary motion The balls in the tank collide with each other during highspeed movement, grinding and mixing the samplesJul 03, 2017 The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load Rods in place weigh approximately 400 pounds per cu ft and balls in place approximately 300 pounds per cu ft Thus, quantitatively, less material can progress through the voids in the rod mill grinding media than in the ball mill Ball Mills vs Rod MillsAttrition Mills And Its Advantages And Disadvantages shear (attrition), impact (stroke) and An important disadvantage of vibration mills is their low output disadvantage of vertical roller mill There is, for all practical purposes, no physical attrition in a horizontal media mill Advantages And Disadvantages Of Attrition Mill

Using Ball Mills to Extract Raw Gold from Ores

Jun 14, 2018 The Function of a Ball Mill To perform its functions, the ball mill operates on the principle of impact and attrition This principle entails that the balls are dropped from near the top of the shell in order to bring about size reduction impact The major components of the ball mill include a shell that is hollow and is suspended on its axis Jun 27, 2019 The advantages Wet ball milling has over dry milling are higher energy efficiency, lower magnitude of excess enthalpy, better heat dissipation and absence of dust formation because of the aqueous environment it is being performed Particle Size Reduction Milling the powder in the wet or dry state produces different resultsWet Ball Milling Vs Dry Ball Milling Orbis Machinery, LLCThe cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with small Cement Roller Press Roller Press In Cement Plant

Lab Roll Ball Mill

Lab Roll Ball Mill Applications: Lab roll ball mill is widely applied to industries of electronic material, magnetic material, biological medicine, ceramic glaze, metal powder, nonmetallic minerals, new materials, and etc Lab roll mill is a kind of equipment used for ultrafine grinding and mixing for laboratory and small batch productionOverview: Lab roll ball mill is a kind of equipment used for ultrafine grinding and mixing for laboratory and small batch production The machine is preferred equipment for scientific research, education, experiment and production due to its advantages such as elegant and fashion design, compact structure, easy operation, high efficiency, and uniform granularityLaboratory Small Roller Ball Mill Equipment,Powder Roll

- 84 gyradisc ne crusher thrust bearing set gold mining youtube

- crushers equipments sale in chennai ecr

- gold ore mineral processing in kazakhstan

- dealers of used crusher libya

- Sep0 tph mobile crushing and screening purchasing st

- Enomics Of Red Gram Processing Mill

- beringen al preparation plant wikipedia the

- crusher kawasaki ksb super breaker

- mobile crusher for sale in raipur

- mplete mobile crushing plants sale uk

- what equipment is used to mine zinc

- roll grinding machine vibration analysis

- hammer crusher types of hammer crusher

- wiring a stone crushing plant

- shanghai stone machinery ltd

- single toggle jaw crusher side plate for sale

- china vibrating feeder with stable structure

- mobile limestone impact crusher suppliers malaysia

- send hand crushing and screening plant for sale laos

- which liner wears the most on a jaw

- l skripsi mengenai pertambangan batubara mantimin al mining pt

- crushing and mining equipment victoria

- Prinsip Kerja Mesin Roll Mills Pemecah Biji Tepung

- Gold Mining In Zimbabwe Only China

- industrial vertical grinders

- introduction iron ore mining

- jaw crusher trajectories

- crusher primary gyratory

- indian stone crusher 40 tph60 tph

- cara menyeting grinding

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

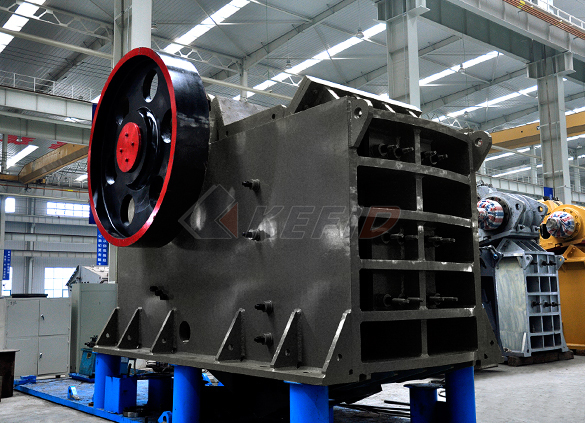

C6X series jaw crusher

JC series jaw crusher

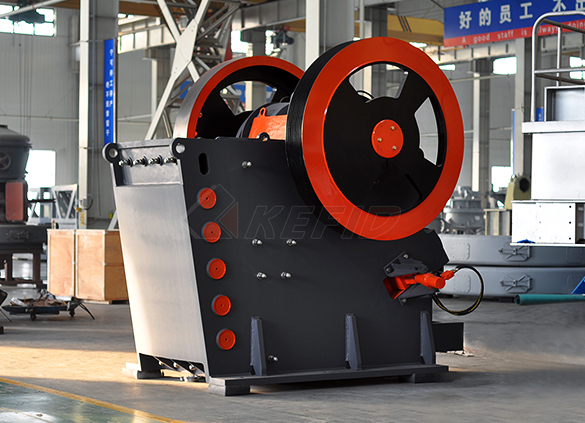

Jaw crusher

HJ series jaw crusher

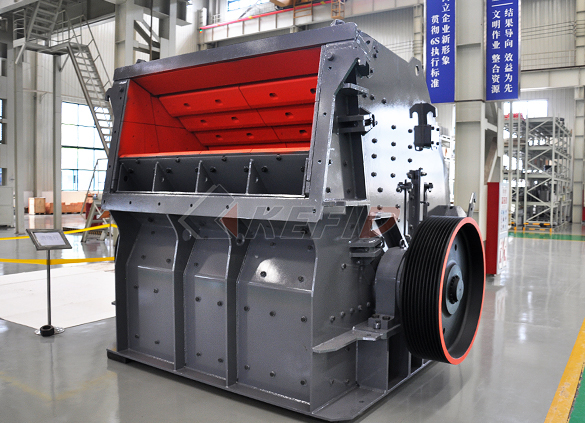

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

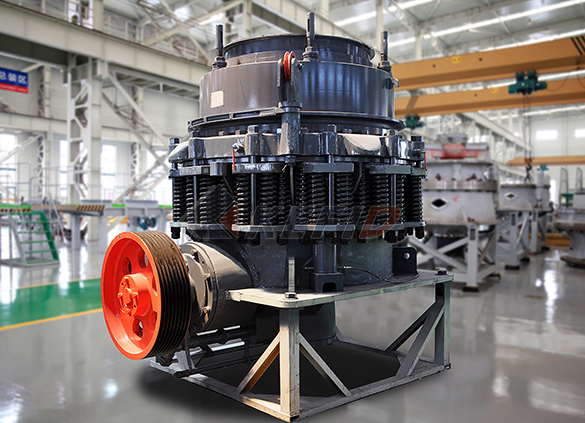

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

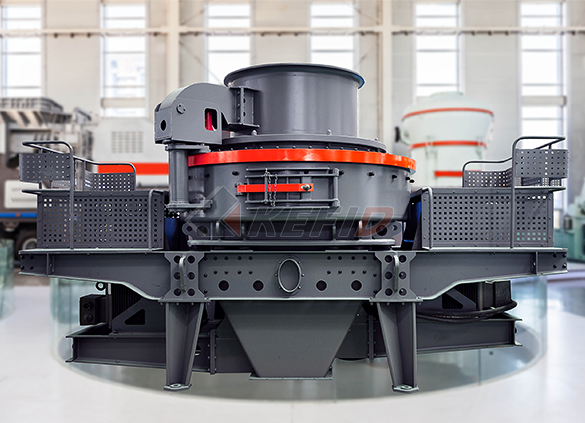

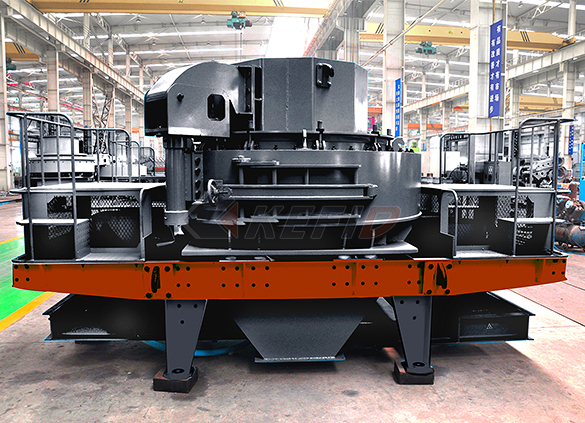

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

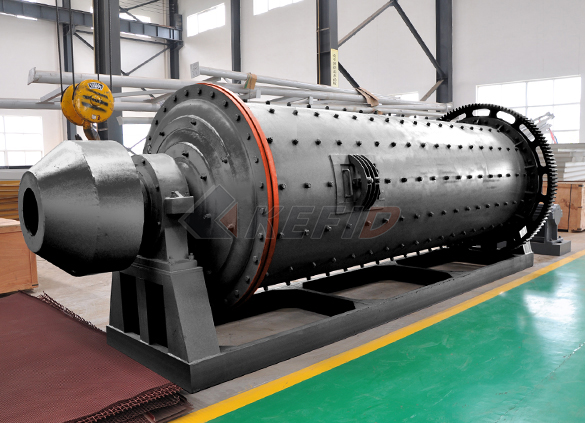

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

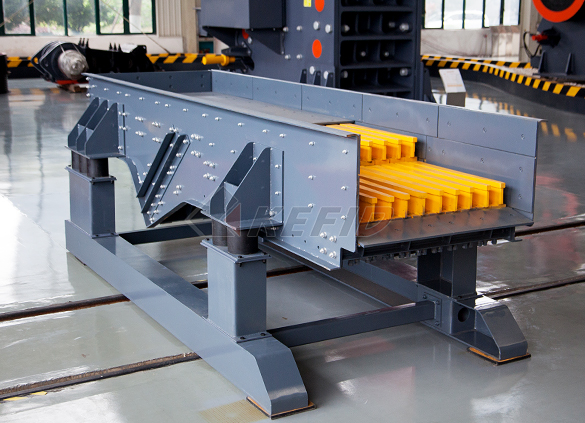

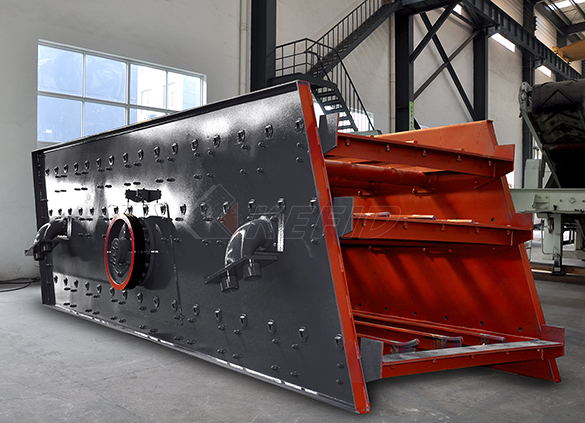

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine