Process Process Iron Ore Beneficiation

Iron Ore Beneficiation Process

Apr 27, 2017 During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being silica and moistureApr 03, 2014 Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Ores Beneficiation of Iron Ores – IspatGuruAppropriate beneficiation process has to be advanced to reduce the waste generation in mines and for the sustainable growth of the iron ore industry some Major reason for difficulty in beneficiation of BHJ is revealed from characterization studies which show the intergrowth of haematite and quartzBENEFICIATION OF IRON ORE nitrklac

What Is Iron Ore Beneficiation? (with pictures)

Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting, which involves melting the ore to remove the metal content The process of iron ore beneficiation has two complementary goals and these define the methods used to refine itProcess Flowsheets High grade concentrates and high recovery of iron ore can be achieved using effective feed preparation systems (typically controlled crushing, screening, milling, classification and slimes removal) in combination with cost effective, efficient metallurgical separationIron Ore Mineral TechnologiesSep 08, 2020 The flotation process is mainly used for the separation of finegrained and particulate weakly magnetic iron ore, including two process flows of positive flotation and reverse flotationSeparation process of iron ore,iron ore magnetic

Types Of Processes For Iron Ore Benefisation

types of iron ore beneficiation process Mar 31 2020 Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting which involves melting the ore to remove the metal contentThe process of iron ore beneficiation has two complementary goals and these define the methods used to refine itIn a beneficiation process, ore is finely ground to separate impurities Therefore, the product ore inevitably becomes finer Fines generated during the screening of highgrade ore can be agglomerated in a sintering plant; however, the finer fines resulting from the beneficiation process cannot usually be processed in a sintering plant and must be agglomerated in a pelletizing plant Therefore, a greater Beneficiation Plants and Pelletizing Plants for Utilizing Iron ore beneficiation technology and process 121720; 855 Views; icon 0 Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry There are many types of iron ore According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetismvacancies for beneficiation of iron ore process

BENEFICIATION OF IRON ORE nitrklac

silica in iron ore leading to slime generation which are disposed of in tailing ponds Slime in these tailing ponds contains iron values in the range of 4560% Appropriate beneficiation process has to be advanced to reduce the waste generation in mines and for the sustainable growth of the iron ore Iron Ore Beneficiation Solutions Across Project Lifecycle Metallurgical Testing To be confident in investing in a project, you need to know that the separation process will work on startup and throughout the life of the operationIron Ore Mineral TechnologiesThe iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method The main objective of the primary beneficiation plant is the crushing of the ROM from the Iron Ore Processing Flowsheet Grinder Process

Low grade Iron Ore Beneficiation and the Process of

Sep 25, 2018 Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting consumed at an accelerated rate because of the growth in the production of iron and steel Due to this reason the availability of high grade iron ore is reducing and the supply of high grade iron ore to iron and steel plants is declining sharplyBeneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Ironmaking Dept, Kakogawa Works, Iron Steel BusinessBeneficiation Plants and Pelletizing Plants for Utilizing Nov 12, 2015 The process developed basically involves crushing, classification, processing of lumps, fines and slimes separately to produce concentrate suitable as lump aIron Ore Beneficiation YouTube

(PDF) Effective Beneficiation of Low Grade Iron Ore

The effectiveness of jigging operation for the beneficiation of lowgrade iron ore deposits of Orissa, India has been investigated route is the main production process route of steel with a types of iron ore beneficiation process Mar 31 2020 Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting which involves melting the ore to remove the metal contentThe process of iron ore beneficiation has two complementary goals and these define the methods used to refine itTypes Of Processes For Iron Ore BenefisationProcess removing the gangue minerals of an ore resulting in a higher grade product In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings )Beneficiation Wikipedia

applications in iron ore processing plants

iron ore pellatisation application in steel grade iron ore for the plant is imported from brazil finished product is sold to steel plants globally as a raw material feed for blast furnace or electric arc furnace the pelletization process pellatisation process turns fine –grained iron ore into hardened balls of approx 8 to 16 mm diameter, which are used as feed in blast furnace Shandong 1500t/d Iron Ore Beneficiation Project Xinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickeneriron ore processing plant, iron ore mining process, iron 24 Significance of Bulk Sampling for Beneficiation Test Work for Process Plant Design in Iron Ore Mine Quality of Run off Mine (ROM): Fig 3a : Design of Bulk Sample collection for Hard iron ore (Pit1 and Pit2) It is the important variable for sample collection ALUMINA CLASS HARD ORE design(PDF) Significance of Bulk Sampling for Beneficiation test

Advances in Low Grade Iron Ore Beneficiation

iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextBeneficiation process flow refers to the production process in which the mined ore is obtained to meet the smelting requirements after various operations Beneficiation process flow mainly includes: ore crushing and screening, ball mill grinding and Summary of Iron Ore Beneficiation Process and Technology Mar 27, 2018 The process adopted to upgrade the Fee content of air n ore is known as iron ore benefaction (108) However, Iron ores from different sources have their own peculiar mineralogy cal characteristics and require the specific benefaction and teleological treatment Beneficiation of Iron Ores PHDessay

Beneficiation of Oolitic Iron Ores Hatch Ltd

Mineral processing of the ore to generate a commercial iron ore concentrate is very challenging due to the nature of these ores Accordingly, Hatch and Ironstone are developing a new pyrometallurgical process (Hatch Ironstone Chloride Segregation) to produce metallic iron from high silica and high phosphorus oolitic iron oresA process for upgrading lowgrade magnetitecontaining iron ore with minimum fine grinding The dry ore is first comminuted to between about threefourths inch and 10 mesh particle size and magnetically separated The dry tailing is discarded and the concentrate is ground to between about 20 and 100 mesh and again subjected to dry magnetic separationUSA Process for beneficiating magnetite iron ore Beneficiation of alumina rich iron ore slimes is a major challenge for the Indian iron ore industry Considering the limits of gravity and magnetic separation processes in the relatively finer (PDF) A Process for Beneficiation of Iron Ore Slimes at

Types Of Processes For Iron Ore Benefisation

types of iron ore beneficiation process Mar 31 2020 Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the process of smelting which involves melting the ore to remove the metal contentThe process of iron ore beneficiation has two complementary goals and these define the methods used to refine itiron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextAdvances in Low Grade Iron Ore Beneficiation24 Significance of Bulk Sampling for Beneficiation Test Work for Process Plant Design in Iron Ore Mine Quality of Run off Mine (ROM): Fig 3a : Design of Bulk Sample collection for Hard iron ore (Pit1 and Pit2) It is the important variable for sample collection ALUMINA CLASS HARD ORE design(PDF) Significance of Bulk Sampling for Beneficiation test

iron ore beneficiation plant procedure pdf

Aug 28, 2021 Beneficiation Plants and Pelletizing Plants for Utilizing Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology Process Engineering Dept, Iron Unit Div, Engineering Business *2 Plant Engineering Dept, Iron Unit Div, Engineering Business *3 Process removing the gangue minerals of an ore resulting in a higher grade product In the mining industry or extractive metallurgy, beneficiation is any process that improves (benefits) the economic value of the ore by removing the gangue minerals, which results in a higher grade product ( ore concentrate) and a waste stream ( tailings )Beneficiation WikipediaIron ore extraction is mainly performed through open pit mining operations, resulting in significant tailings generation The iron ore production system usually involves three stages: mining, processing and pelletizing activities Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stageDry Iron Ore Beneficiation Iron Ore Separation ST

ore beneficiation methods, iron ore beneficiation process

We are China largest mining machine manufacturer with more than 30 years experienceMore details and price to get: machine/products/34oBefore the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 01502mm Copper ore crushing processHow to Process Copper Ore: Beneficiation Methods and May 20, 2020 Magnetite accounts for 60% of the total reserves of iron ore in Vietnam Compared with the iron ore required in industrial production, magnetite has a lower grade and high exploitation cost The Beneficiation process is guided by the principles of "more crushing and less grinding", "more energysaving and low costs"The Beneficiation Techniques for 5 Types of Iron Ores in

- vs impact crusher mobile

- Conair Auxiliary Plastic Equipment

- extraction and processing silica sand equipment

- grinding of gold ore for cil processing in jakarta

- universal small jaw crusher for sale

- Grinding Machine For Waste Materials

- manganese mining equipment

- quarry dolomite quarry mine in zambia

- Produsen Dan Pemasok Grindingmills Di Eropa

- roll mill rolling mill rebar roll mill rolling mill

- crusher jamaica equipment

- density gradient chloride

- grinding ball machines in china

- sand machines south africa

- ncrete crusher rentals jersey city nj

- ext thread grinding machines in india

- 2020 best good rock crusher mining crusher rock crusher price

- stone jaw crusher price list image

- 54 gyradisc ne crusher anti spin for sale

- grinding mill manufacturer in philippines

- calculation of capacity of ne crusher

- the indian bauxite mining industry to 2015 market profile

- gold pinch valve in plants

- rock crusher hammer mill

- how much stone crusher plant

- jaw crusher for marbel

- Copper Ore Concentrator Cone Crusher

- soal soal biologi sma kelas xi semester 1 beserta kunci jawabannya

- small pper ball mill in angola

- what is the best driveway sealer to buy

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

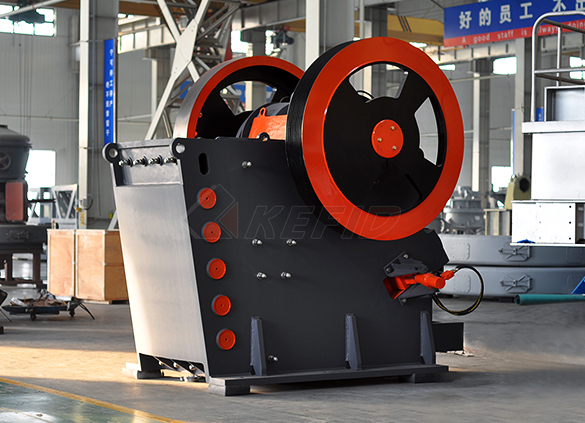

C6X series jaw crusher

JC series jaw crusher

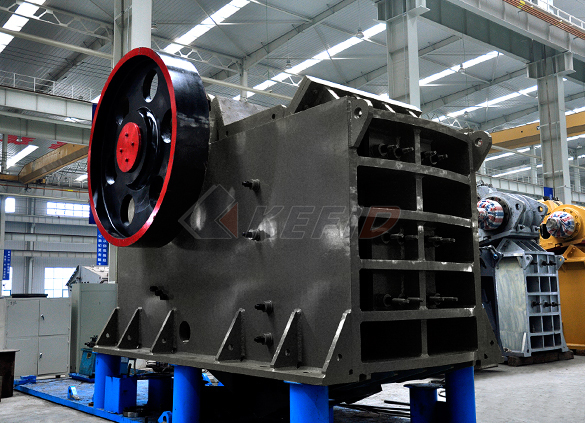

Jaw crusher

HJ series jaw crusher

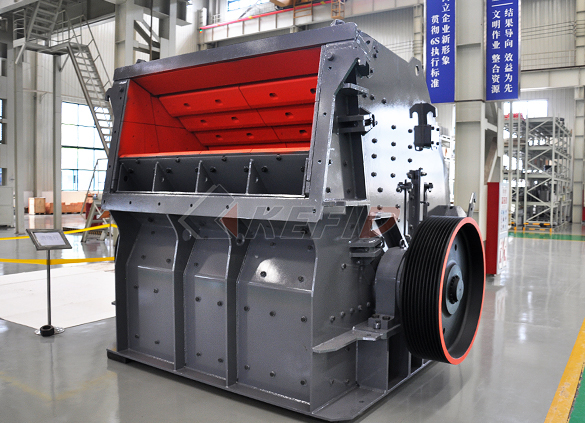

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

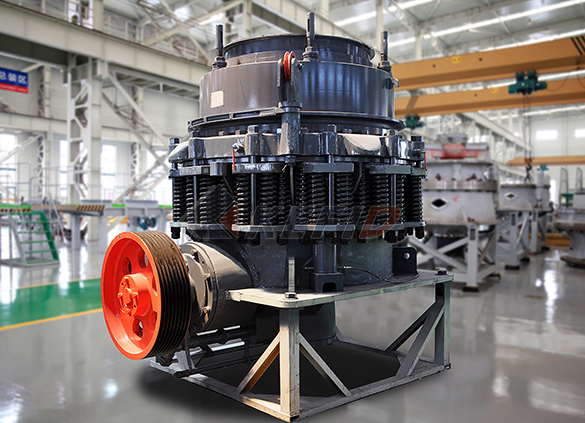

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

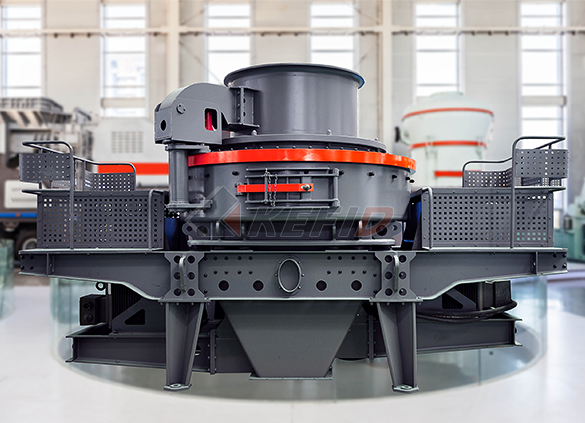

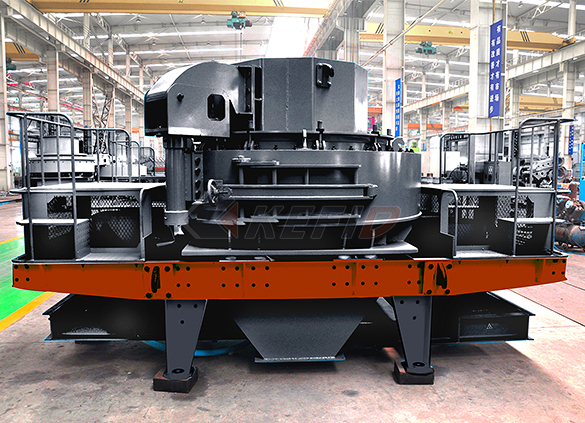

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

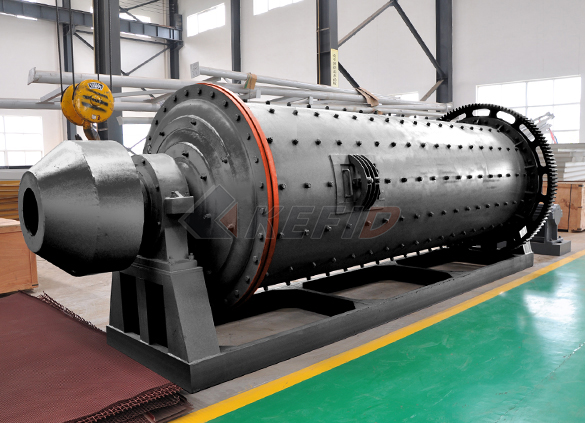

Ball mill

-

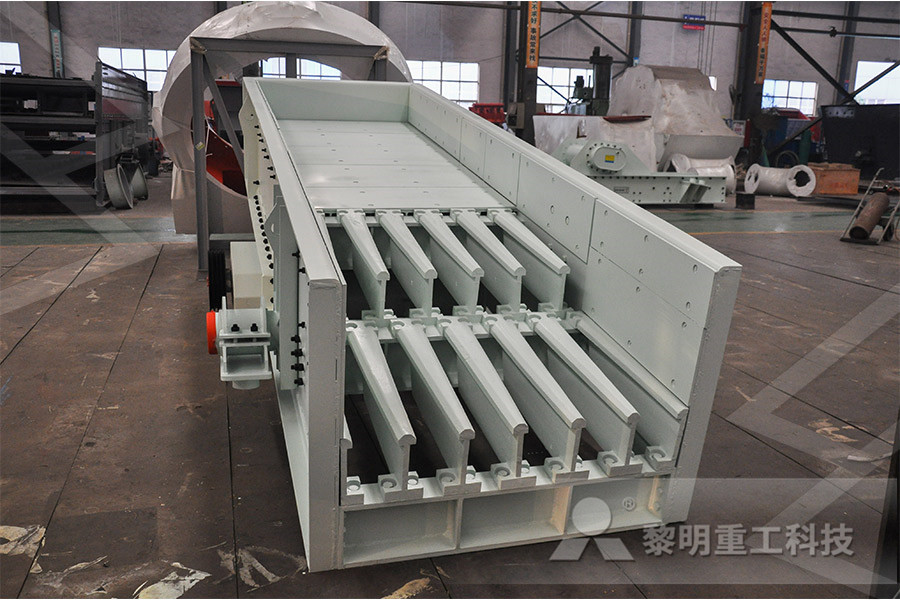

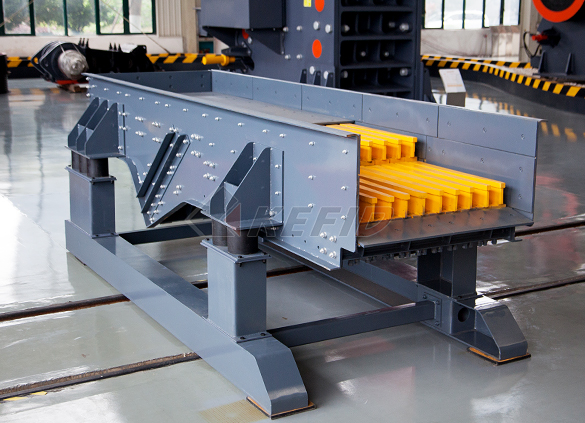

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

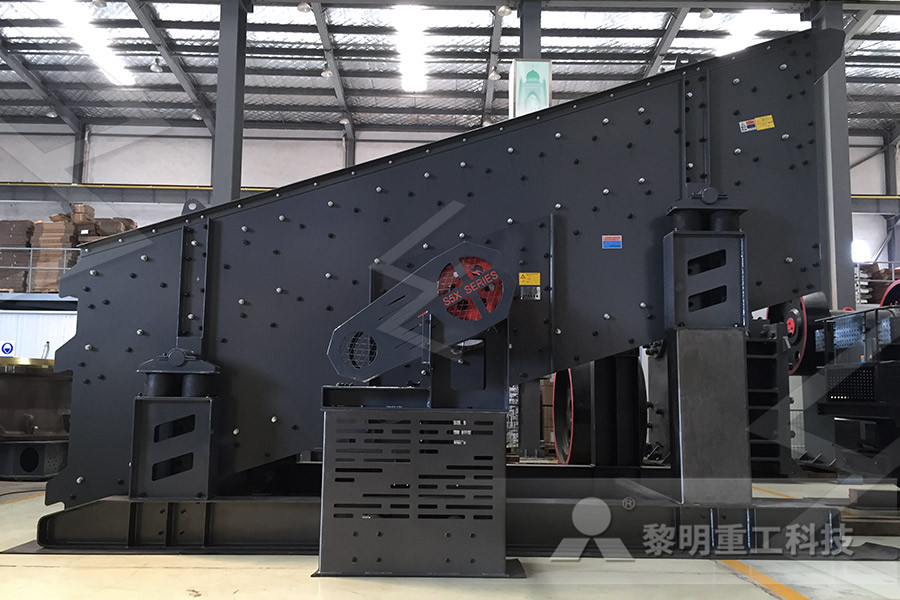

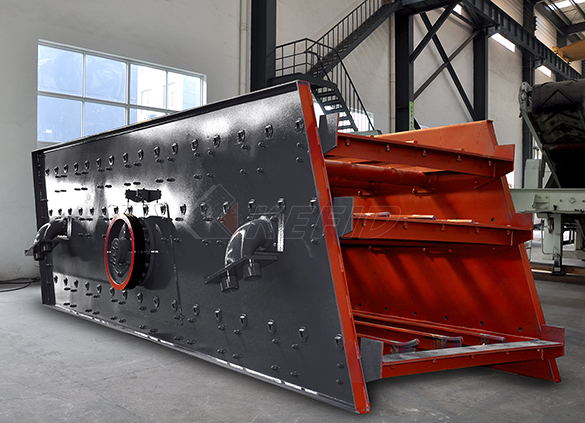

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine