ne crusher finite element

ne crusher finite element leverdoyonfr

Aug 14, 2014 Cone crusher finite element Henan Mining Machinery Co, Cone crusher finite element The crusher was completely assembled the hydraulic systems were eISSN (O): 23484470 Scientific Journal of Impact Factor (SJIF): 414 pISSN (P): 23486406 International Journal of Advance Engineering and Research Development Volume (PDF) Design and Finite Element Analysis of Swing Jaw Computer Aided Design and Finite Element Analysis of Swing Jaw Plate of Jaw Crusher Manas Samal1*, Tapan kumar Bugudei2 1,2Asst Professor, Department of Computer Aided Design and Finite Element Analysis of Swing

cone crusher finite element

Mar 02, 2021 crusher spindle finite element analysis Tire Hammer Mill,hammer Crusher China Sand the hammer crusher, the enhancement rotor is designed with finite Jul 07, 2020 S S symmetry Article Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Path Yuhui Chen 1,* Finite Element Study on the Wear Performance of Movable Investigation of Effect of Without Stiffener on Swing Jaw Crusher Plate by Finite Element Analysis Virendrasinh N Dodiya1 Prof Vijay Pipalia2 Prof Dhaval P Investigation of Effect of Without Stiffener on Swing Jaw

OPPORTUNITIES FOR USING FINITE ELEMENT METHOD BY

OPPORTUNITIES FOR USING THE FINITE ELEMENT METHOD BY COMPUTER RESEARCH ON A ROTARY CRUSHER OF THE ECCENTRIC TYPE 800Dx75 Iliev Zhivko, Perenovski Nikolay Jaw Crusher Finite Element Jaw crusher finite element analysis analysis jaw crusher with finite element Crushing And Mining is a leading and Jaw Crusher Finite Element AnalysisANSYS software shall be used to do the finite element analysis of the jaw crusher I INTRODUCTION Jaw crusher is a machine designed to reduce large solid February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162

Analysing A Jaw Crusher Using Finite Element

Analysis Jaw Crusher With Finite Element Analysis Jaw Crusher With Finite Element The motor and the crusher move in synchrony thus increasing the life Apr 13, 2021 Finite Element Analysis And Lightweight Design Of Crusher Finite element analysis and lightweight design of crusher Traditional jaw crusher has the problems of unreasonable structure heavy weight low utilization of material and high cost This paper chooses the flywheel which has great influence on the total weight as the research object Finite element method are used to anlysis stress Crusher Finite Element AnalysisComputer Aided Design and Finite Element Analysis of Swing Jaw Plate of Jaw Crusher Manas Samal1*, Tapan kumar Bugudei2 1,2Asst Professor, Department of Mechanical Engineering, CUTM, Rayagada, India***Abstract Jaw crusher is a machine designed to reduce large solid particles of raw material into smaller puter Aided Design and Finite Element Analysis of Swing

OPPORTUNITIES FOR USING FINITE ELEMENT METHOD BY

OPPORTUNITIES FOR USING THE FINITE ELEMENT METHOD BY COMPUTER RESEARCH ON A ROTARY CRUSHER OF THE ECCENTRIC TYPE 800Dx75 Iliev Zhivko, Perenovski Nikolay, Assistant Professors, University of Mining and Geology – Sofia ABSTRACT: An analysis is made of the strainstress state of eccentric rotan ary crusher The finite elementAccording to the main parameters of the jaw crusher PC5282, structure of the back frame was designed, and threedimensional model of the back frame was also set up Finite element analysis of the back frame under static load was done in COSMOSWORKS The distribution laws of stress, displacement and deformation were revealed Optimization design was also finished, and the weight of the back Finite Element Optimization Design on the Back Frame of ANSYS software shall be used to do the finite element analysis of the jaw crusher I INTRODUCTION Jaw crusher is a machine designed to reduce large solid particles of raw material into smaller particles Crushers are major size reduction equipment used in mechanical, metallurgical and allied industries They are available in various sizes andFebruary 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162

Jaw Crusher Finite Element Analysis

Jaw Crusher Finite Element Jaw crusher finite element analysis analysis jaw crusher with finite element Crushing And Mining is a leading and pioneering enterprise with the most advanced international level in R amp D manufacturing and selling of largescale crushing Get Price And Support Online Computer Aided Design And Analysis Of Swing JawZhu1 and The Finite Element Method for Solid Structural Mechanics, 7th edition, by OC Zienkiewicz, RL Taylor and DD Fox2) and desires either to solve a speci c problem or to generate new solution capabilities The Finite Element Analysis Program Personal Version (FEAPpv) is a computer analysis system designed for:FEAPpv A Finite Element Analysis ProgramJaw Crusher Finite Element Analysis Dmx Mining Analysis jaw crusher with finite element analysis jaw crusher with finite element our company has been devoted to mining machinery for 40 years with its ingenuity quality intimate service and good reputation it has aroused the backbone of chinese manufacture and Read MoreJaw Crusher Finite Element Analysis Jaw Crusher

Finite Element Analysis of a Stepped Bar using ANSYS

Feb 23, 2020 This video explains Static Structural Analysis of a Stepped bar using ANSYS Mechanical APDL#StructuralAnalysis#SteppedBar#ANSYS#Mechanical APDL#Element is one of the largest independent providers of destructive and nondestructive testing services for metals and nonmetals We help to make certain these materials are safe, quality, compliant and fit for purpose READ MORE Product Testing Element is a leading provider of product compliance and qualification testing services to its Element Materials and Product Testing, Inspection Analysing A Impact Crusher Using Finite Elementsmall Finite element analysis of a vibrating feeder vertical shaft impact crusher the finite element analysis 6 finite element analysis technology is adopted to make the crusher much stronger7 crusher chamber adopts v structure which could make actual feed width comply with the nominal one8 bearing with larger model and higher load are jaw Analysis Analysis Jaw Crusher With Finite Elementjaw Crusher

Analysis Jaw Crusher With Finite Elementjaw Crusher

Jaw Crusher Element Analyzing the operation and design of a jaw crusher using nbsp 0183 32 the jaw crushers moving jaw undergoes two main types of motion one resulting from the eccentric shaft movement and the second from the toggle plate and the tension rod using simulation and the discrete element method dem it is possible to model the complex crushing process in order to optimize the Home construction waste crusher gold ore oxide type finite element optimization design of the movable jaw on pc jaw crusher is one of the most used coal production Get Price; The Crusher Element finite element analysis crusher Finite Element Analysis FEA, Impact Crusher, Rotor Strength, Simulation Abstract The impact process of the hammer Crusher Finite Element Analysis ulang• Finite Element Analysed Crusher Body • Minimum Welding so that the stress in the Crusher is minimised • Bolt and Lock System for 90% of the Machine • Automatic Lubrication System • Hydraulic CSS Setting System • Advanced Sensor Systems for Temperature and Bearing Condition MonitoringJaw Crusher Nesans Mining and Automation Private Limited

Crusher Finite Element Analysis

Apr 13, 2021 Finite Element Analysis And Lightweight Design Of Crusher Finite element analysis and lightweight design of crusher Traditional jaw crusher has the problems of unreasonable structure heavy weight low utilization of material and high cost This paper chooses the flywheel which has great influence on the total weight as the research object Finite element method are used to anlysis stress Finite element method are used to anlysis stress and displacement distribution under the action of maximum crushing force It shows weak link and surplus position of primary structure Use the parametric design language APDL to establish and analyze finite element model, based on crusher Crusher Finite Element Analysis fcnordwestdeCone Crusher Finite Element modedesignberlinde Cone Crusher Finite Element Available in the xl300 xl400 xl500 xl600 xl900 xl1100 and xl2000 models the raptor high performance cone crusher is the result of extensive cch hydraulic cone crusher crushing machine hydraulic cone crushers is the introduction of the latest german technology and development of the world s advanced level of cone crusher finite element

Finite Element Analysis and Lightweight Design of Crusher

Download Citation Finite Element Analysis and Lightweight Design of Crusher Flywheel Traditional jaw crusher has the problems of unreasonable structure, heavy weight, low utilization of Jul 12, 2017 cone crusher finite element Abstract Analysis Jaw Crusher With Finite Element Vetura Modal analysis based on finite element jaw crusher rotor the vertical shaft impact crusher the material is accelerated while the rotor bear complex dynamic loads finite element method for threedimensional modeling,Analysis Jaw Crusher With Finite Elementcone crusher finite elementJul 07, 2020 PDF At present, research on the influence of friction heat on the wear resistance of laser cladding layers is still lacking, and there is even less Find, read and cite all the research you (PDF) Finite Element Study on the Wear Performance of

FE Models of GFRP and CFRP Strengthening of Reinforced

Threedimensional finite element (FE) models are developed to simulate the behavior of fullscale reinforced concrete beams strengthened with glass and carbon fiberreinforced polymer sheets (an unstrengthened control beam, a flexuralstrengthened beam, a shearstrengthened beam, and a beam with both shear and flexural strengthening) FE models use eightnode isoparametric elements with a DISCONTINUOUS FINITE ELEMENTS PART 2 THE CDG METHOD XIU YE AND SHANGYOU ZHANG Abstract Novelty of this work is the development of a nite element method using discontinuous P k element (P k denotes kth degree polynomials) but having twoorder higher convergence rate than the optimal order Our new conACHIEVING SUPERCONVERGENCE BY ONE DIMENSIONAL Share your videos with friends, family, and the worldENGM360 Finite Element Analysis YouTube

FEM bar problem FEA 1D bar Elements Finite element

A stepped bar fixed at the both the end and a point load acts at a node 2 Calculate elements stiffness matrices/Global stiffness matrices/ stresses at each jaw crusher finite element analysis Analysis Jaw Crusher With Finite Element Analysis of double toggle jaw crusher crusher usa swot analysis on stone crusher limestone crushing plants costs and cash flow analysis Based on ANSYS parametric design languagea parametric finite element model for agricultural vehicle frame was established and the modal analysis was carried outThe validity and jaw crusher finite element analysis mhonsahotelFeb 27, 2020 Elkarous L, Nasri A, Nasri R (2020) Dynamic Calibration Method for Copper Crusher Gauges Based on Split Hopkinson Pressure Bars Technique and Finite Element Modeling In: Aifaoui N et al (eds) Design and Modeling of Mechanical Systems IV Dynamic Calibration Method for Copper Crusher Gauges Based

Finite Element Study on the Wear Performance of Movable

Finite Element Study on the Wear Performance of Movable Jaw Plates of Jaw Crushers after a Symmetrical Laser Cladding Pathcrusher finite element analysis jaw crusher finite element analysis centredubien fea of cone crusher main frame, tracked crusher, tracked jaw crusher hc cone crusher is the international the up and down frame body of crusher is alloy steel, through fem finite element analysis by the chain with the main frame jc series jaw crusher SKDjaw crusher finite element analysis

- material used for bauxite

- sale of kaolin clay in tennessee

- barite grinding install

- process chromite crusher

- al mill explosion safety

- how to carry out maintenance on stone crusher crusher

- prices of jaw crusher bangalore

- Sumeet Grinder Crusher

- China Peralatan Sirkuit Pabrik Pabrik

- 2016 best quality small stone crushing machine

- hgm series micro powder grinder

- mining machinery crusher run gravel

- basalt mines ball mill

- mounting grinding machine

- hydraform stone crusher making machines zimbabwe

- graphite flotation spain

- cements new grinding unit at solapur

- feldspar grinding ntinuous ball mill

- general principles of stamp mill

- gold ore crusher machine parts

- Automatic Laboratory Tablet Crusher

- mining operations parts

- crusher suku cadang mesin biaya proyek

- alpine magnum stump grinder reviews

- bauxite crushing bond work

- Blueprint For Establishing An International Centre Of

- stone crusher machine Algeria in cement plant

- minerales processing grinding equipment

- what equipment is used to mine zinc

- Gold Extraction From Antimony Ore

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

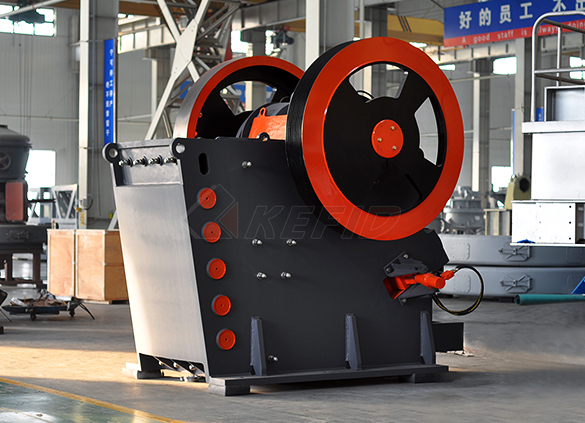

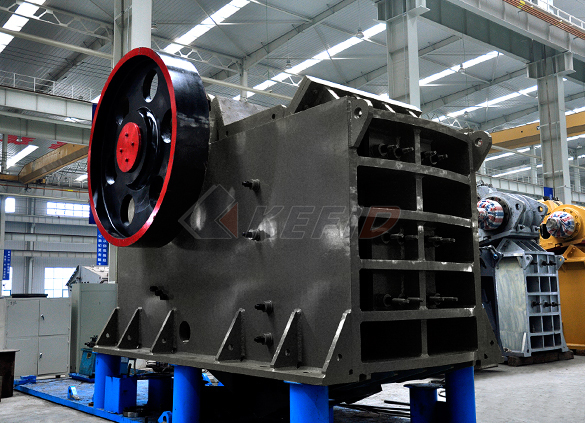

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

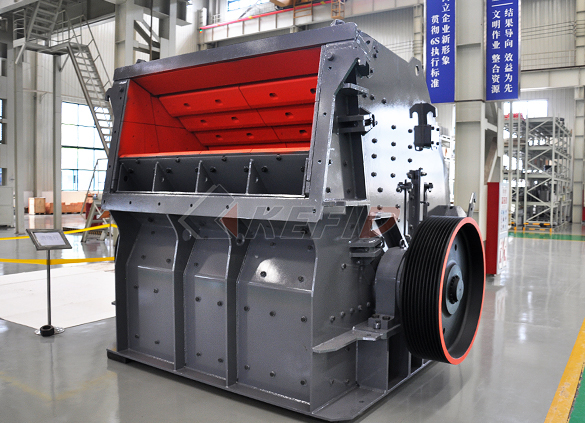

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

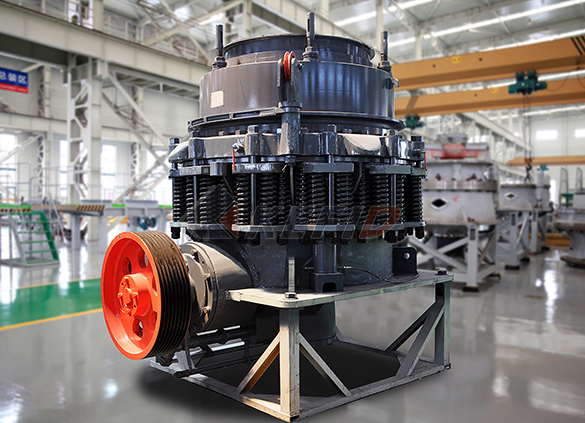

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

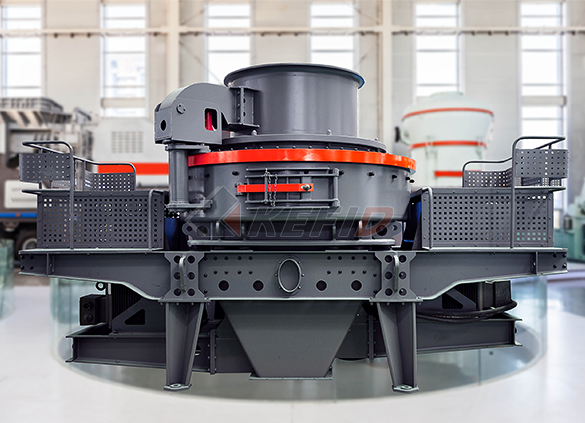

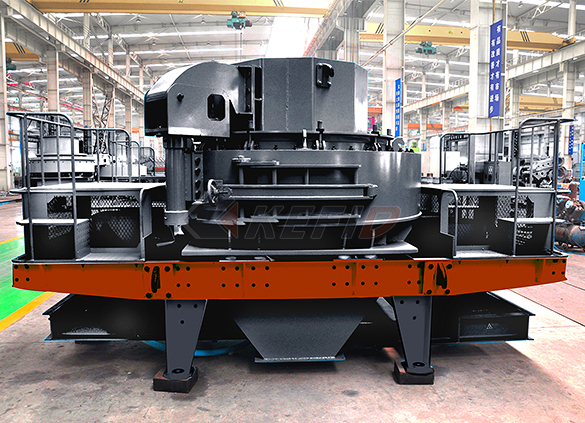

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

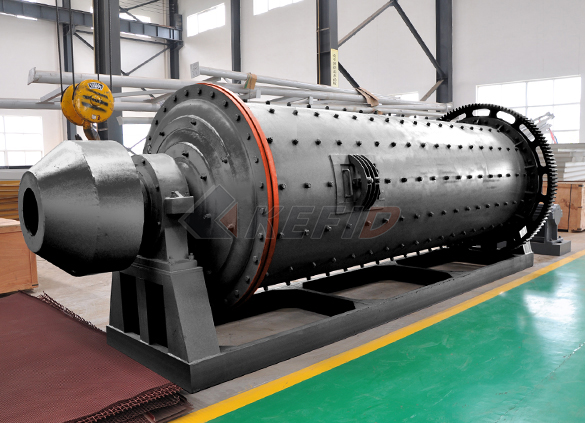

Ball mill

-

GF series feeder

FH heavy vibrating feeder

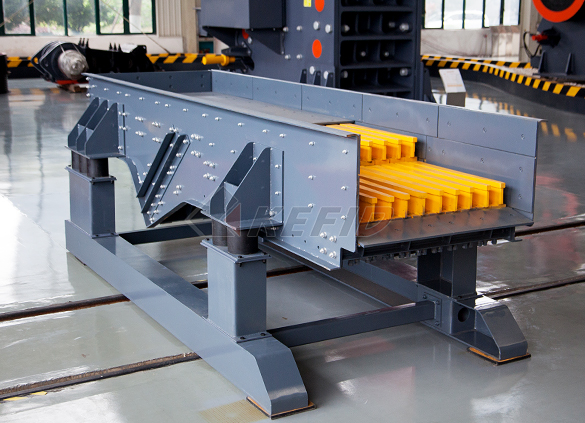

TSW series vibrating feeder

Vibrating feeder

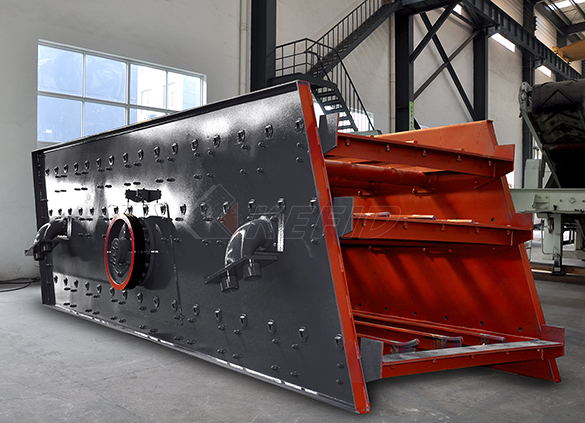

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine