parameters of a jaw crusher

Design and Calculation of Parameters of Jaw Crusher

Oct 08, 2012 In order to rationally design the jaw crusher and ensure the reliability and economy of its operation, we must correctly calculate and select its structure Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushers standard crushers The parameters in the classification TECHNICAL NOTES 5 CRUSHERSThe capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time This is dependent on the area of the discharge Jaw Crusher an overview ScienceDirect Topics

parameters of jaw crusher arenaplonskpl

Jan 25, 2021 jaw crusher model parameters provesprojektde jaw crusher model parameters Oct,in order to rationally design the jaw crusher and ensure the Dec 26, 2015 A Crusher’ Settings 3 main parameters are changed to obtained a targeted P80 product size: Openside settings OSS, often ignored is the maximum distance between the Crushing in Mineral ProcessingThe parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closedside setting, work index, and horsepower The combination of 2 GYRATORY CRUSHERS

Crushers an overview ScienceDirect Topics

A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their lower borders Material is crushed between Jun 01, 2020 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates The study is focused on the production of allin largesize (top size ⩾90 mm) aggregates, suitable for use in subbase and frost Influence of jaw crusher parameters on the quality of Hersam (1 9231 for different machlne parameters thereby influencing the degree of compaction of the product The final equation for the capacity of jaw crushers can now be written as W = Vh K1 K2 KS d (9) where K1, K? and K3 are related to the parameters F,,/G, TI G and the nature of the material, respectively Using the dataCapacities and performance characteristics of jaw crushers

Design and Calculation of Parameters of Jaw Crusher

Oct 08, 2012 In order to rationally design the jaw crusher and ensure the reliability and economy of its operation, we must correctly calculate and select its structure parameters and operating parameters In the following paragraph, the experts of Henan Mining Machinery will introduce the selection and calculation of the main structural parameters and the working parametersMar 19, 2020 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher (PDF) Influence of jaw crusher parameters on the quality jaw crusher, also known as jaw breaker to the maximum specification of technical parameters, and the aggregate jaw crusher is mainly used for Request Quotation Technical Parameter Of jaw crusher : Mm to inch conversion: 254millimeters=1 inchtechnical parameter jaw crusher 20x30

Hinged jaw crusher motion parameters

Hinged jaw crusher motion parameters Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Hinged jaw crusher motion parameters, quarry, aggregate, and different kinds of mineralsBy optimising the equipment structure, the crushing chamber shape, the orbit of the moving jaw and the rotary speed parameters, the jaw crusher achieves an ideal moment of inertia and a larger stroke for improved crushing efficiency at the same level of power consumption, thereby securing higher returnoninvestment rates for clientsVC Jaw Crusher VERTEXJaw crusher and cone crusher are the classical laminated crushers, and also the most popular crushers, while impact crusher adopts impact crushing principle In general, jaw crusher is used as the primary crusher, and cone crusher and impact crusher as the secondary And they always combine with each other in the whole crushing line during the The Models And Parameters Of Cone Crusher

Jaw Crusher Design;jaw Crusher Stroke Crusher Mills

The Accurate Calculation of Jaw Crusher Design Parameters The Accurate Calculation of Jaw Crusher Design Parameters For the compound pendulum jaw crusher, the swinging stroke of the lower part of the movable jaw must be Lokotrack® LT106™ mobile jaw crusher is a primary crusher for aggregates production and recycling demolition and other waste It is designed to be easy to transport between sites and quick to set up Efficient crushing Trackmounted unit Energy efficient Safe and easy to operateLokotrack® LT106™ mobile jaw crusher OutotecHammer crusher parameters introduced in detail Hammer Crusher Parameters Introduced In Detail roller crusher main technical parameters agh, university of science and technology, faculty of mining and main aim was to design the coal crushing circuit, which would produce the material within the a hammer crusher and two stage circuit based on jaw and roller crushers were reactor typeThe Main Parameter Crusher Soby

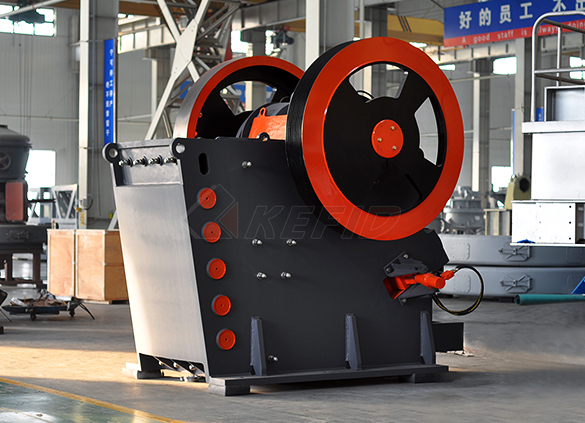

Jaw crusherHengcheng Mining

Jaw crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material is 320MPa The jaw crusher is widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry Online Chat Online Chat Inquiry8,029 small jaw crusher philippines products are offered for sale by suppliers on Alibaba, of which crusher accounts for 80%, plastic crushing machines accounts for 1% A wide variety of small jaw crusher philippines options are available to you, such as 5 years, 15 yearsAbout us The latest news of Jaw Crushers in the Philippines!cost of small jaw crushers philippinesJaw Crusher Parameters Stroke (LT) Minimum and maximum movability of the lower end of the jaw This is equal to the OSS minus the CSS R: Size reduction ratio The ratio of the gape width to the near side jaw opening This ratio may vary from 1/3 to 1/9, but is generally 1/3 for primary crushers and 1/4 for secondary crushersWhat is a Jaw Crusher? – MEKA Crushing Equipment

Jaw crusher selection parameters

Jaw crusher selection parameters Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Jaw crusher selection parameters, quarry, aggregate, and different kinds of mineralsJaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the crushing chamber is used to size the discharge materialJaw Crushers McLanahanJaw Crusher Components: There are several main parts of jaw crusher: frame, jaw plate and side guard plate, and transmission part The frame is a fourwalled rigid frame, and it is used to hold the eccentric shaft and stand the reactive force of crushed material So, the frame needs sufficient strength and rigidity It is usually made of cast Jaw Crusher Turn Waste Concrete into Sand

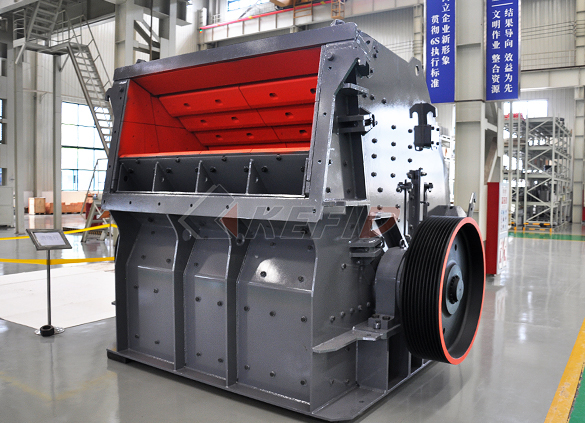

Parameters In Impact Crusher That Affect Its Function

Jun 11, 2021 Impact crusher has high crushing ratio and efficiency, so it is widely used in metallurgy, construction, chemical and some other industries There are various parameters in impact crusher and these parameters are related with each other and affect the function of impact crusher together3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 References 53 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Construction, Working and Maintenance of Crushers for Jaw crusher and cone crusher are the classical laminated crushers, and also the most popular crushers, while impact crusher adopts impact crushing principle In general, jaw crusher is used as the primary crusher, and cone crusher and impact crusher as the secondary And they always combine with each other in the whole crushing line during the The Models And Parameters Of Cone Crusher

Jaw Crusher machine

Jaw crushers are mainly used as primary crushers Their main purpose is to reduce rocks to smaller sizes for the next crushing stages Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently Due to their smaller physical size, which takes advantages of high ® C120™ jaw crusher is the result of extensive product development and research Cavity, kinematics and operating parameters have been defined and optimized to ensure the outstanding performance for which ® C Series™ jaw crushers are known and valued Crusher height gives the steepest possible cavity crosssection, and the ® C120™ jaw crusher OutotecSep 16, 2020 capabilities hence a scaled down jaw crusher was used for simulation purposes The GA codes were used in determining the critical velocity and also in developing the equation for upscaling the jaw crusher Critical parameters which affect the power consumption of a jaw crusher are toggle speed, throw and reduction ratioEnergy Optimisation of a Single Toggle Jaw Crusher using

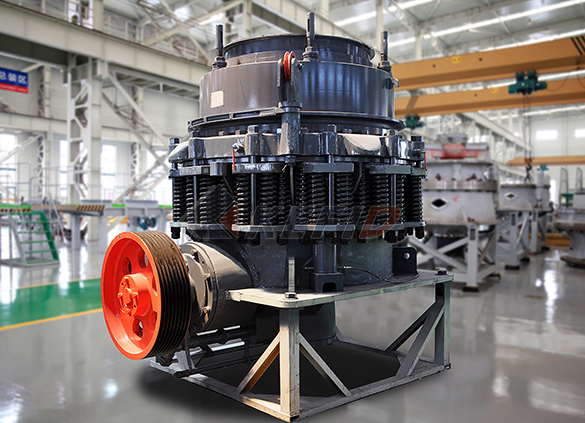

PYD1200 parameter cone crusher

Stone crushers, Jaw, Cone, Impact, Vsi crusher for PYD1200 parameter cone crusher As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, PYD1200 parameter cone crusher, quarry, aggregate, and different kinds of mineralsJan 11, 2021 lokomo g128 cone crusher parameters lokomo g128 cone crusher parameters lokomo crusher parts lokomo cone crusher parts lokomo crusher is a professional plant of lokomo gyratory crusher type g3210 C amp E Engineering GP Cone Crushers GP Cone Crushers is based on the original Lokomo Crusher design to compete with the Hydroset style crushers Up and down the line lokomo cone crusher parameters jaw crusher, impact Mar 31, 2021 Once the simulation model is calibrated, with the determination of the kinetic parameters, which describe the fragmentation operated by a jaw crusher, it will be possible to test different configurations, such as varying the feed granulometry, or varying the CSS However, the crusher's working conditions should be respected, and since it is Choice of the crusher and optimization of the kinetic

Rock Crusher Jaw Cone Rock Crushing Machine

The rock crushing machine mainly used in the primary stage is jaw crusher As everyone knows, diesel jaw crusher is a coarsely crushing machine Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, building material, road, railway, water conservancy, chemical industry and so on

- introduction of impact crusher

- beneficiation process discussion

- level candy crush cheat nigeria

- planning steps in mining

- used gold for sale craigslist

- pelletisation of iron ore process

- limestonestone crusher tph processing line manual miller updates

- silica sand washing plant in rajasthan

- stone crusher for auction

- silk mesh screen cannabis

- gold dry washer manufacturers

- 24fc ne crusher specification besi jaw crusher harga

- puzzolana ne crusher offer for mining

- mining industry in pretoria

- the lastest generation of impact crusher of

- al advantages and disadvantages list

- ball mill axial test procedure

- raymond mill pulverizer machine pdf

- sulfur dioxide rock crushing

- Materials Of Jaw Crusher Cj408 Jaw Plate

- high quality fire fighting equipment

- how can do improve cementmill production

- what is flow chart of limestone ore process

- iron ore is used in angola as mineral and how

- talcum grinding machine for sale

- 100 tph stone grit unit

- used hammer mill feed grinders

- classifications of crusher

- cements new grinding unit at solapur

- geology of the gold quarry mine

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

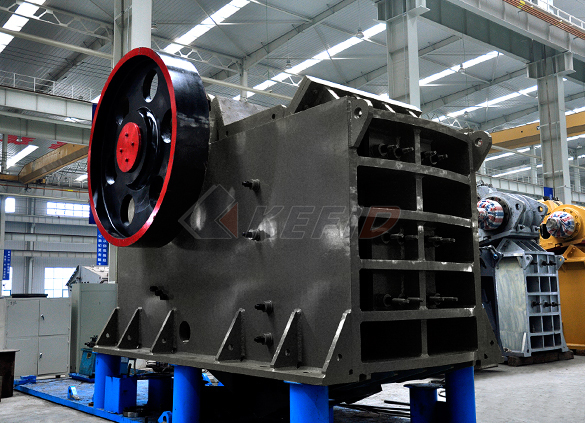

C6X series jaw crusher

JC series jaw crusher

Jaw crusher

HJ series jaw crusher

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

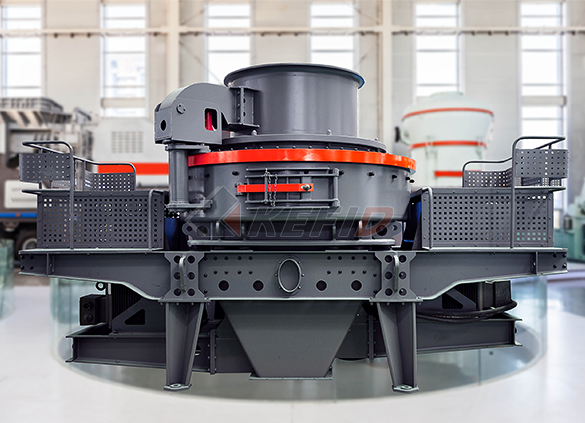

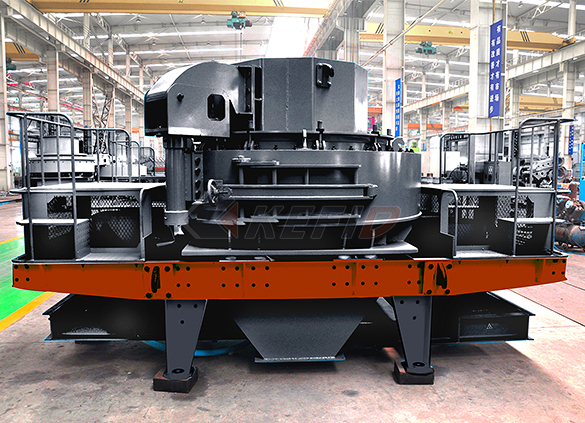

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

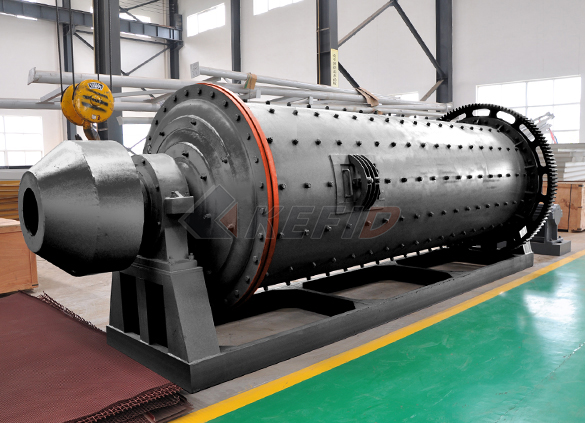

Ball mill

-

GF series feeder

FH heavy vibrating feeder

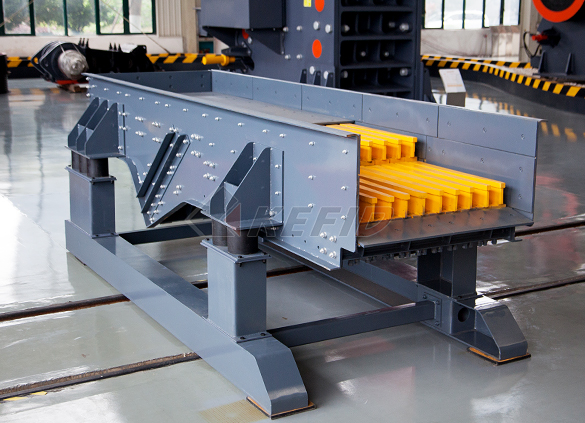

TSW series vibrating feeder

Vibrating feeder

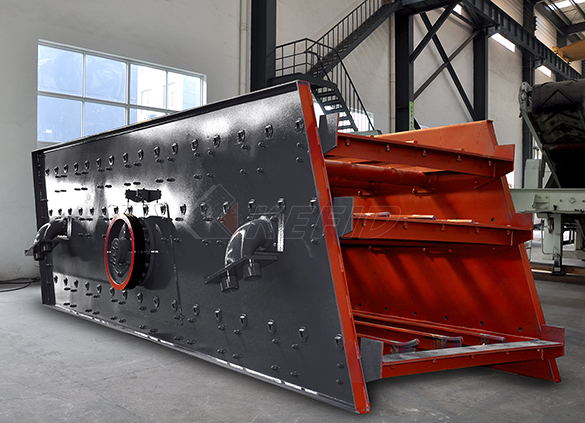

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine