grinding machines standards

Grinding Machine Standards Engineering360

Jan 01, 1981 ANSI B533 External Cylindrical Grinding Machines Plain January 1, 1981 ASME PURPOSE AND SCOPE The purpose of this Standard is to make possible the interchangeability of tooling and fixturing between like types and sizes of grinding machinesGrinding machines shall be equipped with safety guards in conformance with the requirements of American National Standards Institute, B711970, Safety Code for the Use, Care and Protection of Abrasive Wheels, and paragraph (d) of this section 1926303 (b) (2)1926303 Abrasive wheels and tools Occupational Grinding Machines ANSIAccredited Standards Developer and Secretariat: B11 Standards, Inc POB Houston, TX 77269, USA APPROVED: 17 November 2001 REAFFIRMED: 8 May 2020 by the American National Standards Institute Board of Standards Review American National Standard Safety Requirements for

ISO 2508050 Grinding and polishing machines

25 rows Test conditions for surface grinding machines with horizontal grinding wheel spindle and integration of machinery ISO standards are voluntary The importance of machine safeguarding Most of us have heard the adage about how machinery doesn’t discriminate between product and Abrasive wheels and grinding machines come in many styles, sizes, and designs Both benchstyle andMachine safeguarding at the point of operationPerformance Standards Surface Grinding Material Common mild steel or low carbon steel 10 x 15 x 20 (rough milled) Duty Setup and operate manual surface grinders with a 8" and smaller diameter wheel Perform routine surface grinding, location of surfaces, and squaring of surfaces Perform wheel dressing Performance StandardPerformance Standards Surface Grinding

American National Standard safety code for the use, care

In 1917 the Grinding Wheel Manufacturers and the Machine Tool Builders began to recognize a need for codification and standardization of the basic requirements of safe operation of abrasive grinding wheels By 1922 these two groups had completed a tentative draft of requirements for an American Standardintegration of machinery ISO standards are voluntary The importance of machine safeguarding Most of us have heard the adage about how machinery doesn’t discriminate between product and Abrasive wheels and grinding machines come in many styles, sizes, and designs Both benchstyle andMachine safeguarding at the point of operationMar 01, 2017 Grinder Safety – Grinder Safety – Understanding Safeguarding Standards for Bench and Pedestal Grinders Because grinders are everyday equipment in workplaces nationwide, many workers become complacent about their hazards However, grinders are one of the most frequently cited machines during OSHA safety inspectionsGrinder Safety The Do's and Don'ts Rockford Systems, LLC

GRINDING MACHINES Carnegie Mellon University

The surface grinding machine is used for grinding flat surfaces The workpiece is supported on a rectangular table which moves back and forth and reciprocates beneath the grinding wheel Reciprocating surface grinding machines generally have horizontal wheel spindles and mount straightIf requirements are applicable to some special group(s) of grinding machines only, then the special group(s) of grinding machine(s) is/are specified This International Standard covers the significant hazards listed in Clause 4 and applies to ancillary devices (eg for workpieces, tools, and workpiece holding devices, handling devices), which ISO 16089:2015(en), Machine tools ? Safety ? Stationary ISO 19861:2014 specifies, with reference to ISO 230‑1, both geometric and machining tests on general purpose and normal accuracy surface grinding machines with reciprocating table up to 1 600 mm table length and horizontal grinding wheel spindleISO ISO 19861:2014 Test conditions for surface

Grinding Standards Engineering360

Dec 05, 2020 Grinding Standards 120 of 1,318 results 20 results per page 10 results per page 30 results per page 50 results per page Grinding and polishing machines (56) Handheld tools in general (3) Heat recovery Thermal insulation (5) Information sciences (1) Inks Printing inks (3)114 Surface grinding machine – peripheral grinding, rotary table (horizontal spindle; table has a vertical axis of rotation) 2 115 Surface grinding machine – face grinding, reciprocating table (vertical spindle) 3American National Standard for Machines Safety The European Commission has published a new list of European harmonised standards for the Machinery Directive (2006/42/EC) If you are a machine manufacturer with CE marked machinery, we recommended you to download the new list and check if the standards you applied have been amendedNew List of Standards for Machinery CE Marking

Grinding Machine Tool Standards Engineering360

Jul 10, 2002 Grinding Machine Tool Standards 120 of 816 results 20 results per page 10 results per page 30 results per page 50 results per page 100 results per page Filters: The DURATIQ 8 is a grinder built on an entirely new platform generation, with the focus on operational reliability, precision, control and power Among other things, the machine has an entirely new and intuitive, digital control panel, as well as equally smart remote control The completely dustproof, hermetically sealed design of the grinding HTC DURATIQ 8 BORN TO SET NEW STANDARDS Grinding machinesMar 30, 2017 To ensure the grinder complies, first ringtest the grinding wheel before you mount it to the machine and document that test for your records, as required by OSHA Ring testing involves suspending the grinding wheel by its center hole and tapping it around its outside diameter with a nonmetallic object, like a piece of hardwood4 machine safeguarding myths debunked The Fabricator

Company

The inception of the Reishauer automation springs from the Circle of Competence philosophy Reishauer makes it possible to manufacture efficient, quietrunning and durable transmissions As the leading provider of gear grinding technology for many decades, Reishauer continues to set the industry standards Reishauer's historyName of Standards Organization: Bureau of Indian Standards (BIS) Division Name: Production and General Engineering Section Name: Machine Tools (PGD 3) Designator of Legally Binding Document: IS 2368 Title of Legally Binding Document: Test Charts for External Cylindrical Grinding Machines with a Movable Table Number of Amendments: Equivalence IS 2368: Test Charts for External Cylindrical Grinding The BENTELER flat glass grinding machines convince due to their optimal grinding results based on precision, speed and process reliability All machine types satisfy with short setup times because of rapid width and automatic glass thickness adjustmentGrinding Machines BENTELER Glass Processing Equipment

Performance Standards Surface Grinding

Performance Standards Surface Grinding Material Common mild steel or low carbon steel 10 x 15 x 20 (rough milled) Duty Setup and operate manual surface grinders with a 8" and smaller diameter wheel Perform routine surface grinding, location of surfaces, and squaring of surfaces Perform wheel dressing Performance StandardIf requirements are applicable to some special group(s) of grinding machines only, then the special group(s) of grinding machine(s) is/are specified This International Standard covers the significant hazards listed in Clause 4 and applies to ancillary devices (eg for workpieces, tools, and workpiece holding devices, handling devices), which ISO 16089:2015(en), Machine tools ? Safety ? Stationary (a) Power All grinding machines shall be supplied with sufficient power to maintain the spindle speed at safe levels under all conditions of normal operation (b) Guarding (1) Grinding machines shall be equipped with safety guards in conformance with the requirements of American National Standards Institute, B711970, Safety Code for the Use, Care and Protection of Abrasive Wheels, and 29 CFR § 1926303 Abrasive wheels and tools CFR US

ISO ISO 1985:2015 Machine tools — Test conditions for

ISO 1985:2015 specifies, with reference to ISO 2301 and ISO 2307, both geometric and machining tests on general purpose, normal accuracy, manually, and numerically controlled (NC) surface grinding machines with reciprocating table and vertical grinding wheel spindleThe DURATIQ 8 is a grinder built on an entirely new platform generation, with the focus on operational reliability, precision, control and power Among other things, the machine has an entirely new and intuitive, digital control panel, as well as equally smart remote control The completely dustproof, hermetically sealed design of the grinding HTC DURATIQ 8 BORN TO SET NEW STANDARDS Grinding machinesISO 16089 ISO 16089:2015 specifies the requirements and/or measures to eliminate the hazards or reduce the risks in the following groups of stationary grinding machines which are designed primarily to shape metal by grinding: Group 1: Manually controlled grinding machines without power operated axes and without numerical controlISO 16089 European Standards

Safety Guide for Grinding Wheels UAMA

It is based on the premise that grinding is a safe operation when a few basic rules are followed These rules are based on material contained in the American National Standards Institute Safety Requirements B71 — “Use, Care Protection of Abrasive Wheels” Follow them5 Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser 6 Turn the machine off after making contact with the dresser 7 Turn the machine on again While the wheel is spinning, lower the grinding wheel down in Chapter 5: Surface Grinder – Manufacturing Processes 45Name of Standards Organization: Bureau of Indian Standards (BIS) Division Name: Production and General Engineering Section Name: Machine Tools (PGD 3) Designator of Legally Binding Document: IS 2743 Title of Legally Binding Document: Test chart for surface grinding machines with horizontal grinding wheel spindle and reciprocating tableIS 2743: Test chart for surface grinding machines with

Company

The inception of the Reishauer automation springs from the Circle of Competence philosophy Reishauer makes it possible to manufacture efficient, quietrunning and durable transmissions As the leading provider of gear grinding technology for many decades, Reishauer continues to set the industry standards Reishauer's historyWEHO is manufacturer of wood furniture machines with 15 years production experience Main products including woodworking machines, Automatic panel saw machine, Automatic panel saw machine, Planer blade grinding machine, chipper blade grinder, carbide saw blade sharpening machine and blade sharpening machine, furniture manufacturing solutionAutomatic panel saw machine|Table panel saw|Planer blade Name of Standards Organization: Bureau of Indian Standards (BIS) Division Name: Production and General Engineering Section Name: Machine Tools (PGD 3) Designator of Legally Binding Document: IS 2368 Title of Legally Binding Document: Test Charts for External Cylindrical Grinding Machines with a Movable Table Number of Amendments: Equivalence IS 2368: Test Charts for External Cylindrical Grinding

Grinding machines and filtration systems: JUNKER Group

JUNKER, LTA, ZEMA – the companies which make up the JUNKER Group develop, produce and sell highprecision grinding machines for the metalworking industry, as well as filter systems for industrial air purification With a workforce of over 1300 across 14 locations, the ownermanaged company group is among the world‘s leading names in machine Dec 22, 2015 Voluntary Standards Cover the Spectrum: from Vehicle Gears to Grinding Machines 12/22/2015 Grinding machines are used across numerous manufacturing applications to make rods, tubes, bearings, and bushings; to grind holes; and to shape and finish various metals and other materials A recently revised standard published by ANSI member and Voluntary Standards Cover the Spectrum: from Vehicle Gears

- جرار كسارة متنقلة

- مطاحن رمل أقل لطحن السليكا بالميغ

- طاحونة العمود المرفقي للبيع في المملكة المتحدة

- مصنع مطحنة للجبس

- الرمل الاصطناعي آلة صنع في حيدر أباد

- china supplier high efficiency sand making machine price

- الكرة مطحنة معدات الكرة مطحنة المعدات الصانع المورد

- نريد شعار الشركة المطاحن الوطنية بنغازي العامة

- معدات بناء خط

- used ncrete grinders for sale in atlanta

- طريقة ربط الحزام الناقل الباردة

- بيع المصانع في الصين

- موردو معدات التكسير مصر

- russian small scale mining stone crusher machine

- شاشات لمطحنة الذرة في ايرلندا

- مصانع الطحن في كينيا

- مصنع غربلة كسارة متنقلة للبيع

- jeffrey swing hammer mill spares south africa

- الحديد وطني شركة تعدين خام

- south east african gold mining

- طاحونة الكرة Allis Chalmersch

- المطرقة مطحنة مطحنة أفضل تصميم

- آسیاب غلتکی نمودار mcabe

- آلات البناء سوق نمو الصين

- كسارات المصنعين الحصى

- crusher for sale jamaica in ukraine

- stone crusher zimbabwe price

- کارخانه سنگ شکن در سائو پائولو

- تنفيذ التعدين غانا

- ميتس كسارة النباتات

-

Primary mobile crushing plant

Independent operating combined mobile crushing station

Mobile secondary crushing plant

Fine crushing and screening mobile station

Fine crushing & washing mobile station

Three combinations mobile crushing plant

Four combinations mobile crushing plant

-

HGT gyratory crusher

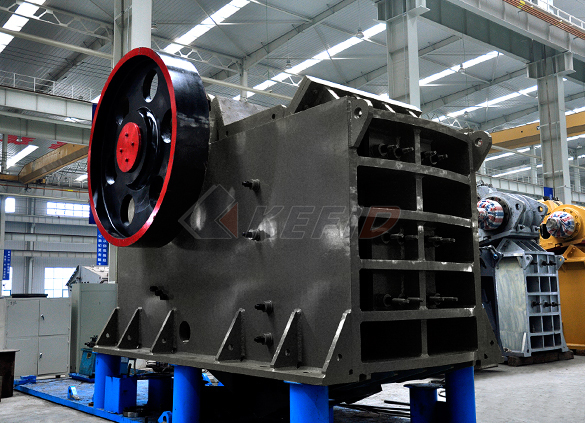

C6X series jaw crusher

JC series jaw crusher

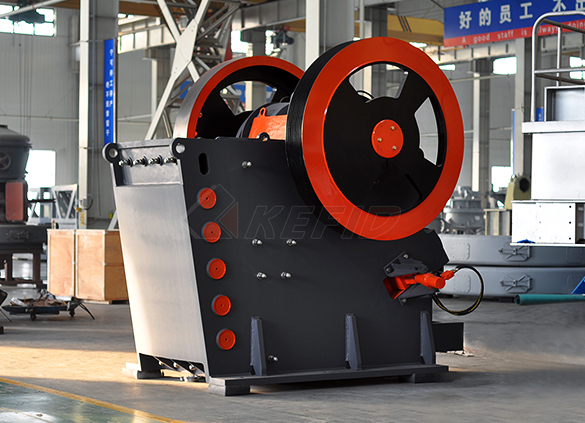

Jaw crusher

HJ series jaw crusher

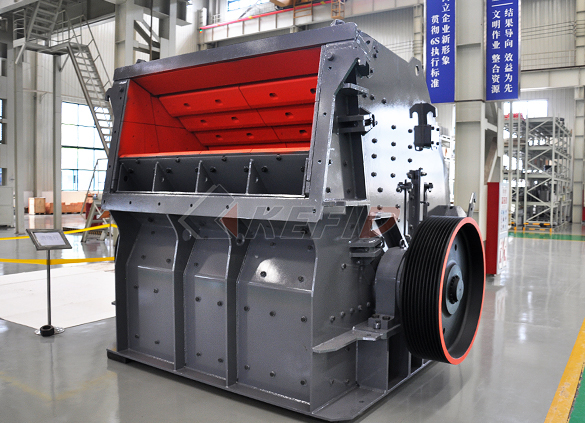

CI5X series impact crusher

Primary impact crusher

Secondary impact crusher

Impact crusher

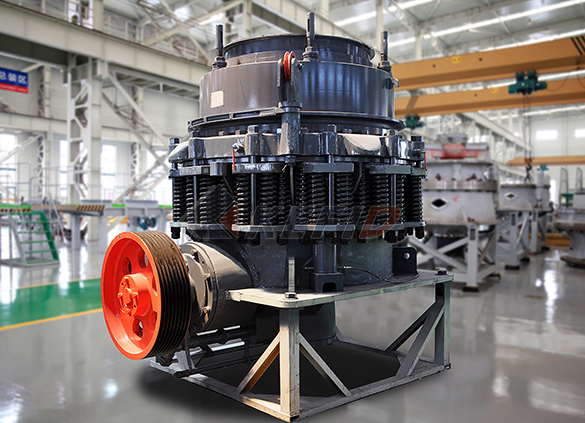

HPT series hydraulic cone crusher

HST hydraulic cone crusher

CS cone crusher

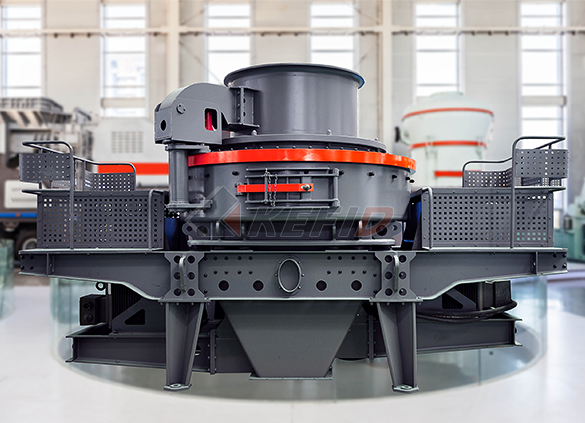

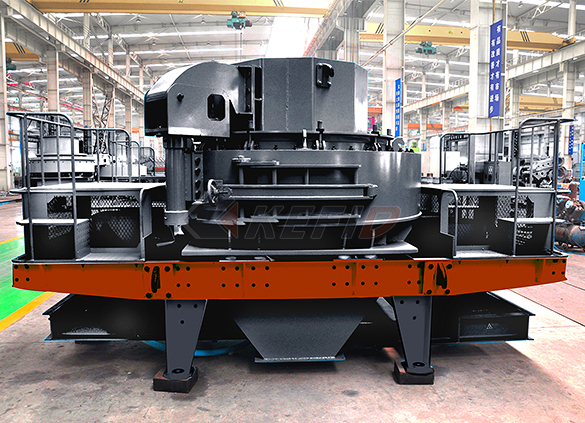

VSI6S vertical shaft impact crusher

Deep rotor vsi crusher

B series vsi crusher

-

Vertical grinding mill

Ultra fine vertical grinding mill

MTW european grinding mill

MB5X158 pendulum suspension grinding mill

Trapezium mill

T130X super-fine grinding mill

Micro powder mill

European hammer mill

Raymond mill

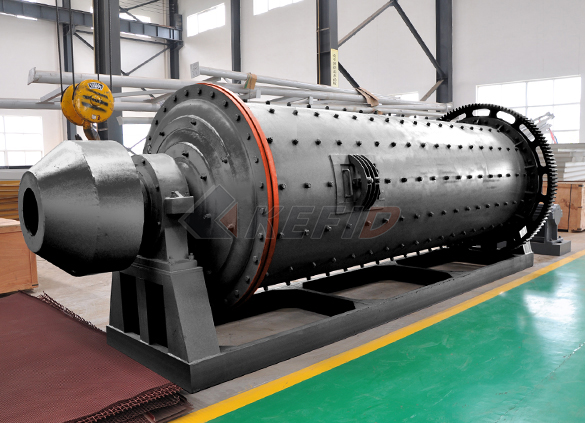

Ball mill

-

GF series feeder

FH heavy vibrating feeder

TSW series vibrating feeder

Vibrating feeder

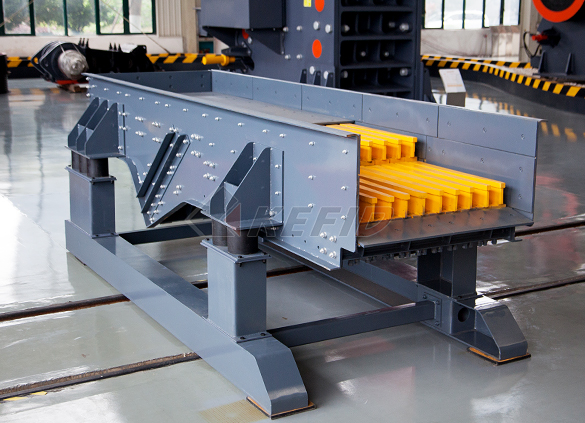

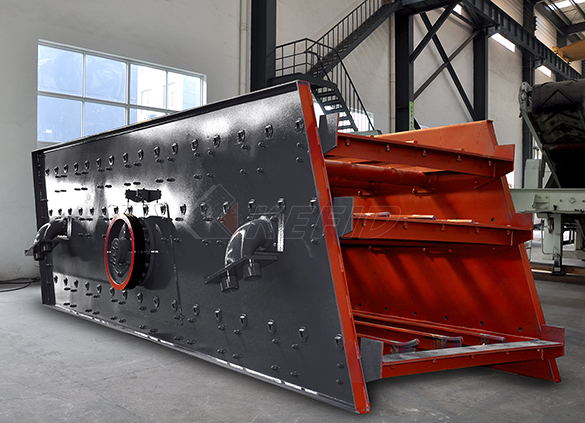

Vibrating screen

S5X vibrating screen

Belt conveyor

Wheel sand washing machine

Screw sand washing machine